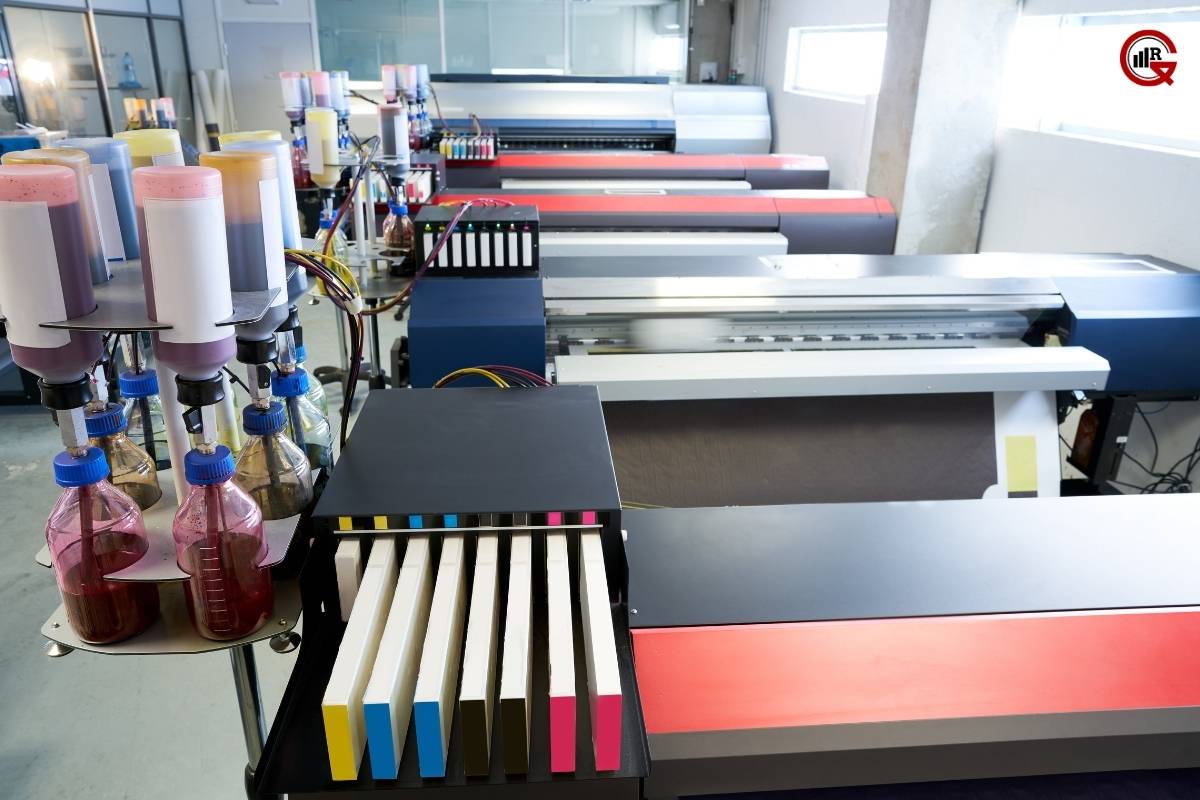

Inkjet printing has revolutionized the way we produce documents, images, and graphics, offering a versatile and efficient solution for various printing needs. From home offices to industrial settings, inkjet printers have become ubiquitous tools for creating high-quality prints with precision and speed. In this article, we will delve into the evolution, applications, advantages, and advancements of inkjet printing (IP)technology, as well as its potential future developments.

Evolution of Technology:

The origins of IP can be traced back to the 1950s when researchers began exploring methods of creating digital prints using droplets of ink. Early inkjet printers relied on analog technologies and piezoelectric or thermal printheads to eject ink onto paper, fabric, or other substrates. These early prototypes laid the foundation for the development of modern IP technology.

In the 1980s and 1990s, inkjet printing underwent significant advancements, with the introduction of desktop inkjet printers for home and office use. These printers offered improved print quality, faster printing speeds, and more affordable consumables, making them accessible to a broader range of users. Concurrently, industrial IP systems emerged, enabling large-scale printing for applications such as signage, packaging, and textile printing.

Applications of Inkjet Printing:

IP technology finds widespread applications across various industries and sectors, including:

Graphic Arts and Publishing: Inkjet printers are widely used for producing high-quality prints for magazines, brochures, posters, and other marketing materials. The ability to achieve vibrant colors, sharp images, and precise text makes IP ideal for graphic arts and publishing applications.

Textile Printing: Digital textile printing using inkjet technology has transformed the textile industry, allowing for the customization of fabrics, garments, and home textiles with intricate designs, patterns, and colors. Inkjet printers equipped with specialized textile inks enable on-demand printing, short production runs, and rapid prototyping in the textile manufacturing process.

Packaging and Labeling: Inkjet printing is widely employed in the packaging industry for printing labels, tags, and packaging materials. The flexibility of inkjet technology allows for the customization of packaging designs, serialization, and variable data printing, catering to the diverse needs of product branding and marketing.

3D Printing: Inkjet-based 3D printing, also known as binder jetting, utilizes inkjet printheads to selectively deposit binding agents onto powder substrates, layer by layer, to create three-dimensional objects. This additive manufacturing process is used in prototyping, rapid manufacturing, and production of complex geometries in industries such as aerospace, automotive, and healthcare.

Functional Printing: Inkjet printing technology is increasingly being used for functional printing applications, including printed electronics, conductive patterns, sensors, and biomedical devices. Inkjet-printed circuits, sensors, and electrodes offer cost-effective solutions for flexible electronics, wearable devices, and point-of-care diagnostics.

Advantages of Inkjet Printing:

It offers several advantages over traditional printing methods, including:

High-Quality Prints: Inkjet printers produce high-resolution prints with sharp text, smooth gradients, and accurate color reproduction, making them suitable for applications that demand exceptional print quality.

Versatility: Inkjet printers can handle a wide range of substrates, including paper, fabric, plastics, ceramics, and metals, allowing for diverse printing applications across different industries and materials.

Cost-Effectiveness: It offers cost-effective solutions for short print runs, on-demand printing, and variable data printing, eliminating the need for costly setup fees and plate changes associated with traditional printing methods.

Environmentally Friendly: It generates minimal waste, as it does not require printing plates or chemical processes typical of offset printing. Furthermore, inkjet printers consume less energy and produce fewer emissions compared to other printing technologies.

Customization and Personalization: It enables customization and personalization of prints, allowing for the creation of unique designs, variable data printing, and mass customization to meet individual preferences and market demands.

Advancements in Technology:

Recent advancements in printing technology have further expanded its capabilities and applications. Some notable developments include:

UV-Curable Inks: UV-curable inkjet inks offer enhanced adhesion, durability, and environmental resistance, making them suitable for outdoor signage, packaging, and industrial applications requiring long-lasting prints on challenging substrates.

Digital Textile Printing: Advances in digital textile printing technology have led to the development of high-speed, high-resolution inkjet printers capable of printing on a wide range of fabrics with vibrant colors and intricate patterns, transforming the textile printing industry.

Functional Inks: The development of functional inks for printing has enabled the fabrication of electronic circuits, sensors, and biomedical devices using additive manufacturing techniques, opening up new possibilities in flexible electronics, wearable technology, and healthcare applications.

3D Printing with Inkjet Technology: Inkjet-based 3D printing systems continue to evolve, offering faster print speeds, larger build volumes, and improved material compatibility for producing complex, multi-material 3D printed parts with high accuracy and resolution.

Digital Packaging Printing: Printing technology is increasingly being adopted for digital packaging printing applications, enabling on-demand production of customized packaging with variable data printing, serialization, and brand protection features.

Future Directions in Technology:

Looking ahead, inkjet printing technology is poised to continue evolving and advancing, driven by ongoing research and development efforts in various fields. Some future directions and potential developments in inkjet printing include:

Nanoparticle Inks: The development of nanoparticle-based inks holds promise for enhancing the performance and functionality of inkjet-printed materials. Nanoparticle inks with tailored properties, such as conductivity, magnetism, or optical properties, could enable new applications in electronics, sensors, and advanced materials.

Bioprinting and Tissue Engineering: Inkjet-based bioprinting technologies are being explored for the precise deposition of living cells and biomaterials to fabricate tissues, organs, and biomedical implants. Advances in biocompatible inks, printhead technology, and tissue engineering techniques could revolutionize regenerative medicine and personalized healthcare.

Additive Manufacturing Integration: Inkjet printing technology is being integrated into additive manufacturing processes, such as selective laser sintering and stereolithography, to enhance material deposition, surface finish, and part quality. Inkjet-based additive manufacturing systems could enable the production of complex, multi-material components with high resolution and accuracy.

Sustainable Printing Solutions: With increasing emphasis on sustainability and environmental stewardship, printing technologies are being developed with eco-friendly inks, recyclable substrates, and energy-efficient printing processes. Green printing initiatives aim to minimize waste, reduce energy consumption, and lower carbon emissions associated with printing operations.

Smart Printing Systems: Inkjet printers equipped with sensors, artificial intelligence, and internet-of-things (IoT) connectivity enable smart printing systems capable of self-monitoring, predictive maintenance, and real-time optimization. Smart inkjet printing solutions streamline workflow, improve productivity, and enhance user experience in various printing applications.

Conclusion:

Printing technology has undergone remarkable evolution and transformation since its inception, revolutionizing the printing industry and enabling new applications across various sectors. From high-quality graphics and textiles to functional electronics and 3D printing, inkjet technology continues to push the boundaries of what is possible in printing and manufacturing. With ongoing advancements in materials, printhead technology, and digital workflow solutions, the future of inkjet printing holds promise for even greater innovation, efficiency, and customization in printing and fabrication processes.