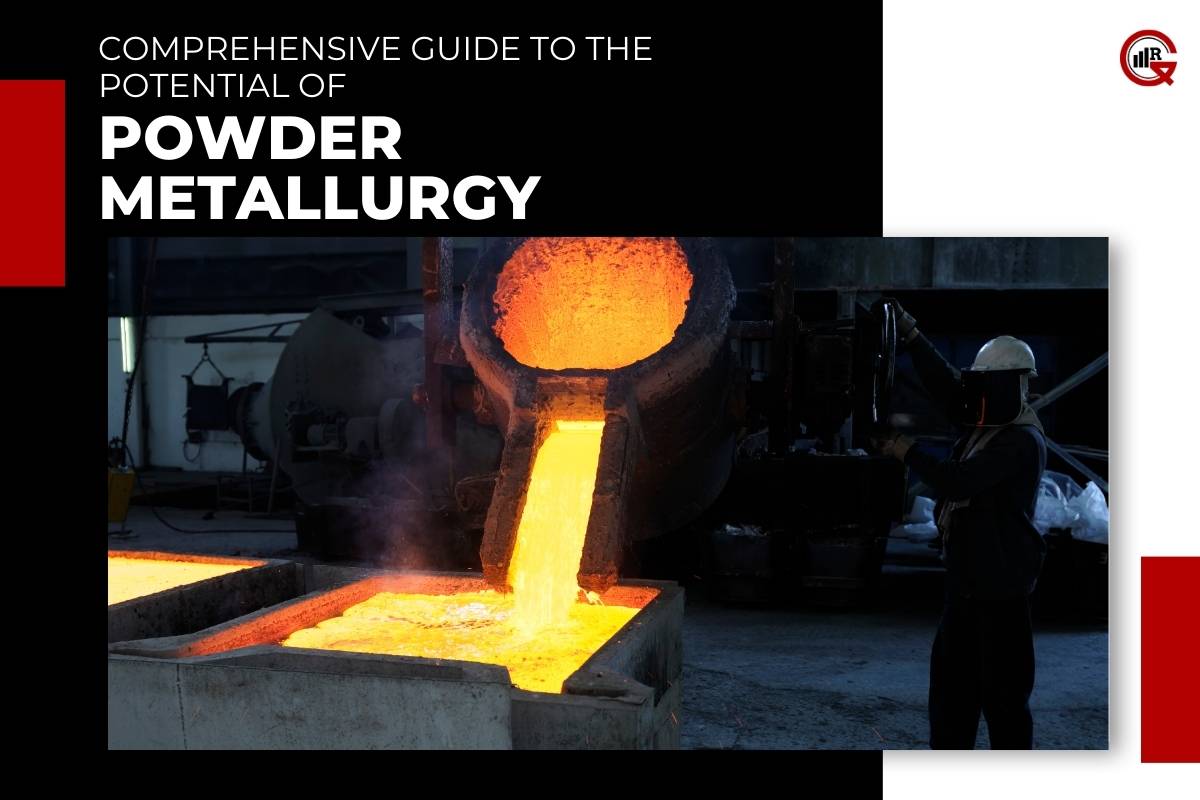

Powder metallurgy (PM) is a highly versatile manufacturing process that involves the production of metal components from finely powdered metals. This innovative technique offers numerous advantages over traditional metalworking methods, including enhanced material properties, intricate part geometries, and cost-effectiveness. In this article, we will explore the fundamentals of powder metallurgy, its applications across various industries, and the prospects of this technology.

Introduction to Powder Metallurgy:

Powder metallurgy is a manufacturing process that begins with the production of metal powders, which are then compacted and sintered to create finished metal components. The process typically involves several key steps:

Powder Production: Metal powders are produced through various methods such as atomization, chemical precipitation, and mechanical comminution. These powders can be composed of pure metals, alloys, or blends of different materials.

Powder Compaction: The metal powders are compacted into the desired shape using hydraulic presses or mechanical presses. During compaction, the powders are subjected to high pressure, which causes them to adhere and form a green compact.

Sintering: The green compacts are then heated in a controlled atmosphere to a temperature below the melting point of the metal. This process, known as sintering, causes the particles to bond together through diffusion, resulting in a dense and solid metal component.

Advantages of Powder Metallurgy:

Powder metallurgy offers several advantages over conventional metalworking methods:

1. Material Efficiency:

Powder metallurgy minimizes material waste by utilizing nearly 100% of the metal powder, resulting in cost savings and environmental benefits.

2. Complex Geometries:

PM allows for the production of complex part geometries with precise dimensions and intricate features that are difficult or impossible to achieve through traditional machining techniques.

3. Enhanced Properties:

Sintering enables the creation of metal components with superior mechanical properties, such as high strength, wear resistance, and dimensional stability.

4. Cost-Effectiveness:

PM is a cost-effective manufacturing process, particularly for high-volume production runs, due to its efficiency in material usage and reduced machining requirements.

Applications of Powder Metallurgy:

Powder metallurgy finds wide-ranging applications across various industries, including automotive, aerospace, consumer electronics, and healthcare:

1. Automotive Industry:

PM components are used in automotive engines, transmissions, braking systems, and structural parts. Examples include gears, bearings, bushings, and valve guides.

2. Aerospace Sector:

Powder metallurgy is utilized in aircraft engines, landing gear systems, and structural components due to its lightweight, high-strength properties and ability to withstand extreme operating conditions.

3. Consumer Electronics:

PM is employed in the production of electrical contacts, magnetic components, and connectors used in smartphones, laptops, and household appliances.

4. Healthcare Sector:

PM is used to manufacture surgical instruments, dental implants, orthopedic implants, and medical devices due to its biocompatibility, corrosion resistance, and dimensional accuracy.

Recent Developments and Future Trends:

Powder metallurgy continues to evolve with advancements in materials, processing techniques, and additive manufacturing technologies:

1. Advanced Materials:

Researchers are developing new metal powders and alloy compositions with tailored properties, such as improved strength, corrosion resistance, and thermal conductivity.

2. Additive Manufacturing:

Powder metallurgy is increasingly integrated with additive manufacturing processes such as selective laser sintering (SLS) and binder jetting to produce complex metal parts with rapid prototyping and customization capabilities.

3. Sustainability Initiatives:

There is growing interest in sustainable metallurgy practices, including the recycling of metal powders, the use of renewable energy sources, and the reduction of carbon emissions in sintering processes.

Emerging Trends and Technologies:

Nanostructured Materials: Researchers are exploring the use of nanopowders and nanocomposites in powder metallurgy to enhance material properties such as strength, hardness, and electrical conductivity. These nanostructured materials offer exciting possibilities for applications in electronics, energy storage, and biomedical devices.

Metal Additive Manufacturing: It is closely linked with metal additive manufacturing (AM) processes, such as powder bed fusion and binder jetting. AM technologies enable the fabrication of intricate metal components with high precision and customization, opening up new opportunities for rapid prototyping and on-demand production.

Hybrid Manufacturing: Hybrid manufacturing combines particular metallurgy with conventional machining or forming techniques to create hybrid components with superior performance and functionality. This approach allows for the integration of complex features and materials, such as metal-ceramic composites, in a single manufacturing step.

Digitalization and Industry 4.0: The integration of digital technologies such as artificial intelligence (AI), Internet of Things (IoT), and cloud computing is transforming powder metallurgy into a more connected and data-driven process. Smart sensors and predictive analytics enable real-time monitoring of process parameters, quality control, and predictive maintenance, enhancing efficiency and productivity.

Green Manufacturing Practices: Sustainable manufacturing practices are gaining prominence in metallurgy, driven by environmental concerns and regulatory requirements. Initiatives such as powder recycling, energy-efficient sintering processes, and waste reduction strategies are being implemented to minimize the environmental impact of metallurgy operations.

Challenges and Considerations:

Despite its many advantages, powder metallurgy also faces certain challenges and considerations that need to be addressed:

Material Selection: Choosing the right metal powders and alloy compositions is crucial to achieving the desired properties and performance of powder metallurgy components. The availability of high-quality powders and the ability to control powder characteristics are important considerations.

Process Optimization: Optimizing metallurgy powder processes requires careful control of parameters such as compaction pressure, sintering temperature, and atmosphere composition. Variations in these parameters can affect the density, microstructure, and mechanical properties of the final components.

Cost Competitiveness: While metallurgy offers cost savings in material usage and production efficiency, initial equipment costs and tooling expenses can be significant. Achieving cost competitiveness with other manufacturing methods requires careful analysis of lifecycle costs and economies of scale.

Quality Assurance: Maintaining consistent quality and dimensional accuracy is essential in metallurgy powder to meet stringent specifications and standards. Quality control measures such as process monitoring, inspection techniques, and defect detection are necessary to ensure the reliability and performance of finished components.

Conclusion

In conclusion, metallurgy is a versatile and cost-effective manufacturing process that offers numerous advantages for the production of metal components across diverse industries. With ongoing advancements in materials science, processing techniques, and sustainability initiatives, metallurgy is poised to play a vital role in shaping the future of manufacturing and engineering. As technology continues to evolve, the applications and capabilities of powder metallurgy are expected to expand, driving innovation and efficiency in the global manufacturing sector.