Description

The Global Metal Powder Injection Molding (MIM) Market size was USD 4.55 billion in 2022 and it is expected to grow to USD 10.20 billion in 2030 with a CAGR of 9.76% in the 2023-2030 period.

Global Metal Powder Injection Molding (MIM) Market: Overview

Metal Powder Injection Molding (MIM) is a manufacturing process that combines the principles of plastic injection molding and powder metallurgy to produce complex-shaped metal components. Metal powders are mixed with a thermoplastic binder to create a feedstock that is easily injectable. The feedstock is heated and injected into a mold cavity under high pressure, taking the shape of the mold. After molding, the green part is subjected to thermal debinding, where the majority of the binder is removed, leaving behind a porous structure. The debound parts are then sintered in a high-temperature furnace to achieve the final density and strength of the metal component.

As industries demand more intricate and lightweight components, MIM becomes an attractive option due to its ability to produce complex geometries. For certain applications, MIM can offer cost advantages over traditional manufacturing methods, especially in high-volume production. Ongoing developments in metal powders and binders expand the range of materials that can be processed through MIM, further driving market growth. The increasing trend of miniaturization in various products boosts the demand for small-sized metal components, which can be efficiently produced through MIM. However, the market also faces challenges, such as high initial tooling costs and the need for specialized expertise in MIM process optimization.

Global Metal Powder Injection Molding (MIM) Market: Covid-19 Impact

Many MIM manufacturers faced challenges due to lockdowns, travel restrictions, and labor shortages. Factory closures and limited operations hindered production capacities. The pandemic affected the supply of raw materials and metal powders required for the MIM process, leading to delays and increased costs. Demand for MIM components may have fluctuated depending on the industries served. While some industries, like medical equipment, experienced increased demand, others, such as automotive and aerospace, faced a downturn. The uncertainty caused by the pandemic led some companies to postpone their investments in new MIM projects and technologies. International trade restrictions and border closures impacted the export and import of MIM products and materials.

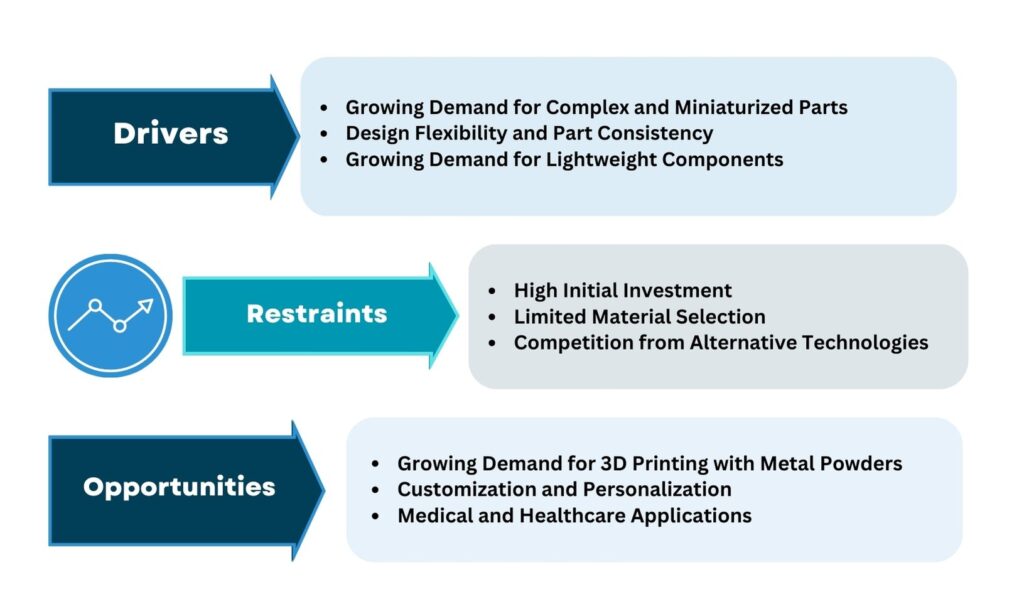

Global Metal Powder Injection Molding (MIM) Market: Growth Drivers

-

Growing Demand for Complex and Miniaturized Parts:

In various industries like automotive, aerospace, electronics, and medical, there is an increasing need for small, intricate, and complex metal components. MIM offers an advantage in producing such parts with high precision and dimensional accuracy, driving its adoption.

-

Design Flexibility and Part Consistency:

MIM allows designers to create complex shapes and features that are not easily achievable with traditional manufacturing processes. This design flexibility enables the production of innovative components with consistent quality.

-

Growing Demand for Lightweight Components:

Industries such as automotive and aerospace are increasingly focusing on lightweight materials to improve fuel efficiency and performance. MIM’s ability to produce lightweight metal components aligns with this trend.

-

Advancements in MIM Technology:

Technological advancements, such as improved injection molding equipment and process optimization, have enhanced the efficiency and capabilities of the MIM process, driving its adoption.

Global Metal Powder Injection Molding (MIM) Market: Restraining factors

-

High Initial Investment:

The initial setup costs for metal powder injection molding can be relatively high, especially for small and medium-sized enterprises. These costs include tooling, equipment, and specialized knowledge required for the process.

-

Limited Material Selection:

While advancements have expanded the range of materials compatible with MIM, the selection of materials is still more limited compared to traditional manufacturing processes like CNC machining or casting. This constraint may limit MIM’s applicability for certain high-performance or specialized applications.

-

Competition from Alternative Technologies:

The quality and availability of Kraft lignin can vary depending on the raw materials and the specific pulping processes used. Inconsistent quality and supply might have posed challenges for potential buyers, especially those requiring a standardized and reliable feedstock.

Global Metal Powder Injection Molding (MIM) Market: Opportunity factors

-

Growing Demand for 3D Printing with Metal Powders:

Additive Manufacturing, particularly 3D printing with metal powders, is gaining popularity in various industries. MIM can complement 3D printing by offering cost-effective production of complex and high-precision metal components, especially for high-volume applications.

-

Customization and Personalization:

With advancements in digital manufacturing technologies, customization and personalization are becoming more feasible. MIM can leverage these trends by offering cost-effective production of customized metal components.

-

Medical and Healthcare Applications:

The medical industry relies on small, complex, and biocompatible components. MIM is well-suited for producing medical devices, surgical instruments, and implants, presenting significant opportunities in the healthcare sector.

-

Aerospace and Defense:

The aerospace and defense industries require lightweight yet high-strength components for aircraft and military equipment. MIM’s ability to produce such parts could lead to greater adoption in these sectors.

Global Metal Powder Injection Molding (MIM) Market: Challenges

-

High Initial Investment and Tooling Costs:

The setup costs for MIM can be relatively high, including tooling and equipment expenses. These costs might deter some companies, particularly smaller enterprises, from adopting MIM for their manufacturing needs.

-

Material Selection and Performance Limitations:

While advancements in material science have expanded the range of materials compatible with MIM, the selection is still more limited compared to traditional manufacturing processes. Additionally, certain high-performance applications may have specific material requirements that MIM cannot fully meet.

-

Complex Process Control:

MIM involves multiple steps, including feedstock preparation, injection molding, debinding, and sintering. Maintaining precise process control throughout these stages can be challenging, affecting the quality and consistency of the final products.

-

Competition from Alternative Technologies:

MIM competes with other manufacturing methods, such as CNC machining, die casting, and metal injection molding (MIM). The choice of the appropriate manufacturing technique depends on factors like part complexity, volume, and cost-effectiveness, which can impact the demand for MIM.

Global Metal Powder Injection Molding (MIM) Market: Segmentation

Based On Material: The market is segmented into Carbon Steel, Stainless Steel, Cobalt Alloy, Tungsten Steel, Tool Steel, Titanium, Carbon Iron Powders, and Others; depending on the materials segmentation. Among these the Stainless Steel Materials dominates the market growth.

Based On End-User: Based on End-user segmentation, the market is further divided into Electronics, Automotive, Sporting Goods, Power Tools, Defense & Firearms, Medical & Dental, Aerospace, and Others. Among these, the Automotive sector is the largest revenue contributor towards the market.

Based On Region: Based on Region, the market is segmented into five key geographical regions namely – North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Global Metal Powder Injection Molding (MIM) Market: Regional Insights

North America, including the United States and Canada, was one of the significant contributors to the MIM market. The region’s strong presence in industries such as aerospace, automotive, medical, and electronics provided ample opportunities for MIM adoption. Additionally, the region’s focus on advanced manufacturing technologies and innovations supported the growth of MIM applications. Europe was another prominent market for MIM, with countries like Germany, the United Kingdom, and Italy being key players. The region’s well-established automotive and aerospace industries, along with its emphasis on precision engineering and high-quality components, drove the demand for MIM. The Asia-Pacific region emerged as a rapidly growing market for MIM. Countries like China, Japan, South Korea, and Taiwan were at the forefront of this growth. The region’s booming automotive, electronics, and medical industries, combined with the availability of skilled labour and technological advancements, presented significant opportunities for MIM expansion. Other regions, including Latin America, the Middle East, and Africa, showed a gradual increase in MIM adoption. These regions presented opportunities for market growth as industries diversified, and there was an increasing demand for small and complex metal components.

Global Metal Powder Injection Molding (MIM) Market: Competitive Analysis

The Global Metal Powder Injection Molding (MIM) Market is driven by various key players such as Indo-MIM Pvt. Ltd, ARC Group Worldwide Inc, CMG Technologies, Parmaco Metal Injection Molding AG, OptiMIM, FloMet LLC, MIM International, FineMIM, PSM Industries Inc, Makuta Technics Inc.

Global Metal Powder Injection Molding (MIM) Market: Recent Developments

- Indo-MIM Pvt. Ltd: n 2020, Indo-MIM introduced Binder Jet 3D printing technology. This technology allows Indo-MIM to produce complex metal parts with high accuracy and repeatability.

- CMG Technologies: In 2022, CMG Technologies expanded its manufacturing capacity by opening a new facility in Suffolk, UK. This new facility has a capacity of 1 million parts per year, and has helped CMG Technologies to meet the growing demand for its products.