In today’s automotive industry, innovation is not just confined to engine power or design aesthetics; it extends to the very infrastructure that connects the various components of a vehicle. Automotive connectors, often overlooked but essential components, play a pivotal role in ensuring seamless communication and functionality within modern vehicles. This article delves into the significance of automotive connectors, their evolving role in vehicle design, and the latest advancements shaping the automotive connectivity landscape.

Understanding Automotive Connectors

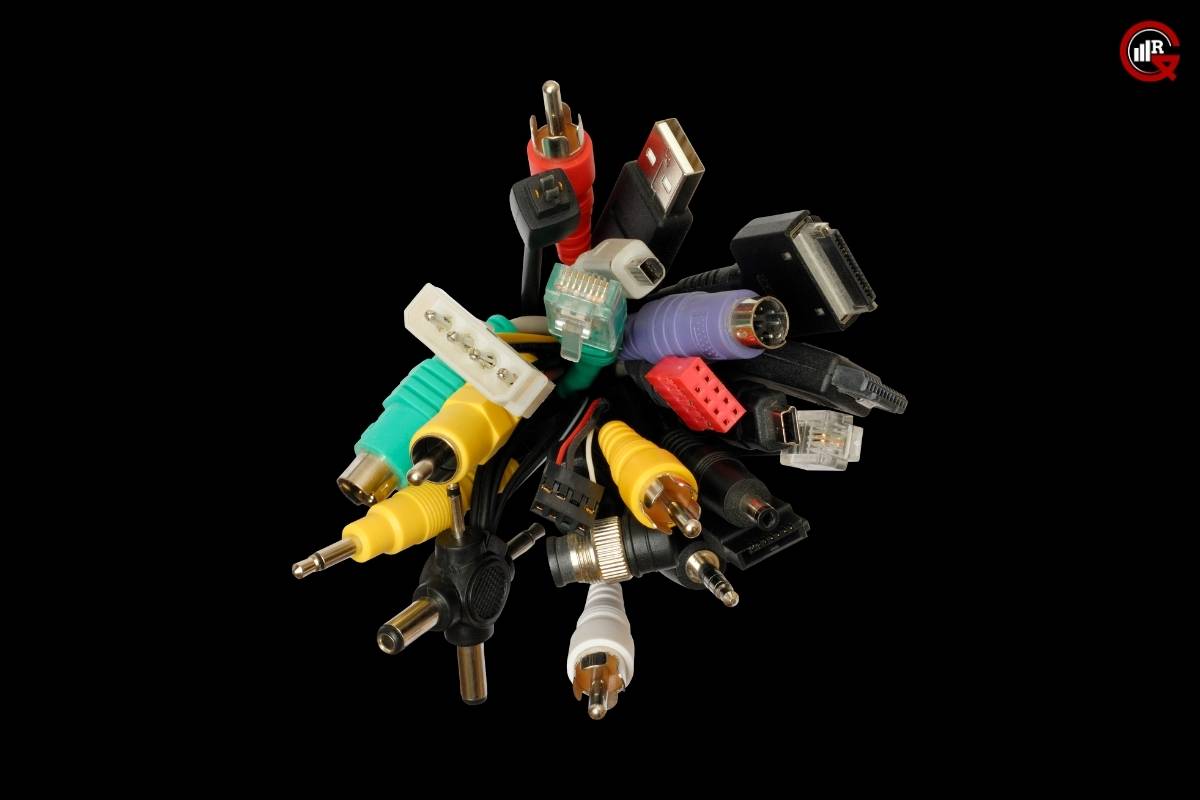

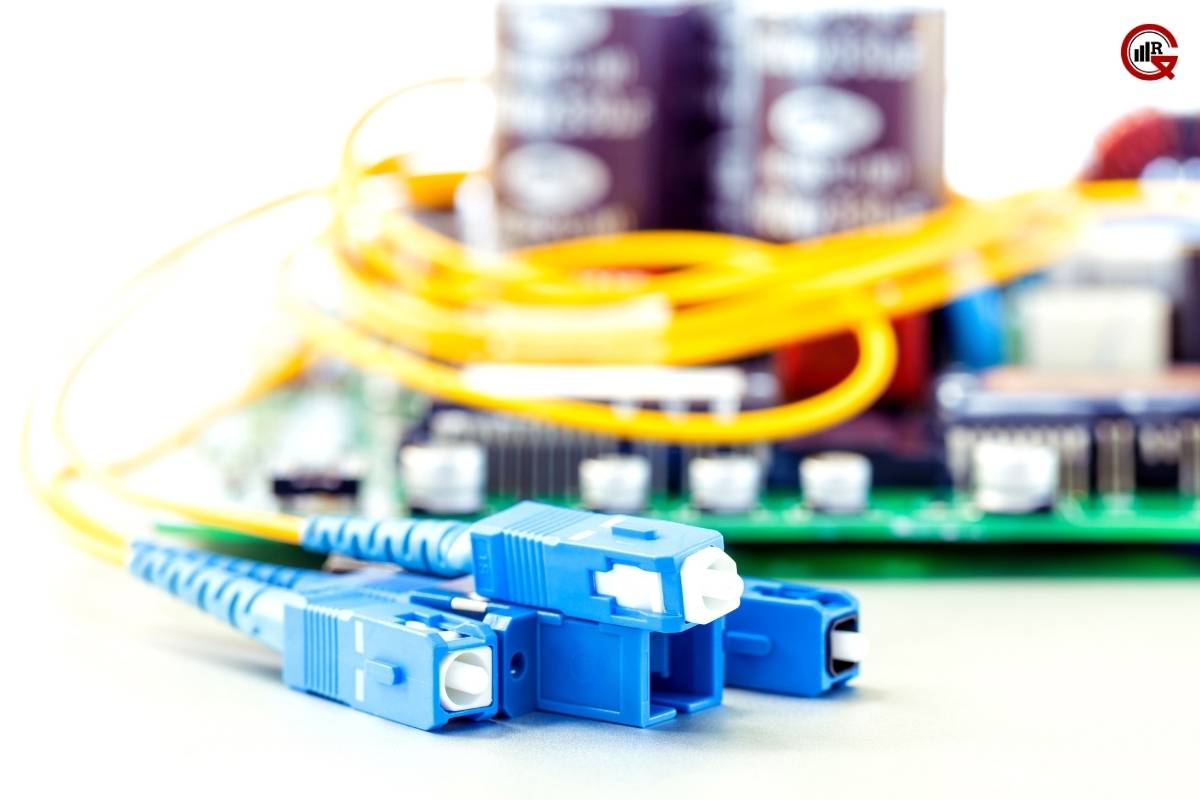

They are electrical components used to establish secure and reliable connections between different electronic systems and components within a vehicle. These connectors facilitate the transmission of power, signals, and data between various vehicle systems, including the engine, transmission, sensors, infotainment systems, and safety features.

Importance of Automotive Connectors

Reliable Electrical Connections: Automotive connectors are designed to withstand the harsh operating conditions encountered in vehicles, including temperature fluctuations, vibrations, moisture, and electromagnetic interference. Their robust construction ensures reliable electrical connections, minimizing the risk of signal loss, malfunction, or electrical failures.

Enhanced Vehicle Performance: By providing a standardized interface for connecting electrical components, connectors contribute to the overall performance and efficiency of modern vehicles. They enable seamless integration of advanced features such as advanced driver-assistance systems (ADAS), electrified powertrains, infotainment systems, and connectivity services, enhancing the driving experience and safety features.

Flexibility and Scalability: Automotive connectors offer flexibility and scalability in vehicle design and manufacturing, allowing automakers to customize and optimize electrical systems to meet specific requirements. Modular connector designs enable easy assembly, maintenance, and future upgrades, reducing production costs and time-to-market for new vehicle models.

Diagnostic and Maintenance Capabilities: Automotive connectors play a crucial role in vehicle diagnostics and maintenance, enabling technicians to access and analyze data from onboard sensors, control units, and electronic systems. Diagnostic connectors provide a standardized interface for connecting diagnostic tools and software, facilitating troubleshooting, fault detection, and repair procedures.

Evolution of Automotive Connectivity

Over the years, automotive connectivity has evolved significantly, driven by advancements in technology, consumer demand for connected features, and regulatory requirements. The automotive industry is witnessing a shift towards electrification, automation, and digitalization, driving the demand for more sophisticated and high-performance connectors.

High-Speed Data Connectivity: With the proliferation of connected vehicles and in-vehicle electronics, connectors are increasingly required to support high-speed data transmission for applications such as in-car entertainment, navigation, telematics, and vehicle-to-vehicle (V2V) communication. High-speed connectors such as USB, HDMI, Ethernet, and CAN (Controller Area Network) are becoming standard features in modern vehicles, enabling seamless connectivity and data exchange.

Electrification and Hybridization: The transition towards electric and hybrid vehicles necessitates the development of specialized connectors capable of handling high-voltage power distribution, battery management, and charging systems. High-voltage connectors, including HVIL (High-Voltage Interlock Loop) connectors, are designed to ensure safety and reliability in electrified vehicles, facilitating efficient power transfer and management.

Miniaturization and Lightweight Design: As vehicle electronics become more complex and space-constrained, there is a growing demand for miniaturized and lightweight connectors that can accommodate densely packed electronic systems without compromising performance or reliability. Miniaturized connectors offer significant advantages in terms of space savings, weight reduction, and improved vehicle aerodynamics, contributing to fuel efficiency and range in electric vehicles.

Sealed and Waterproof Connectors: With the increasing emphasis on vehicle durability and reliability, automotive connectors are being designed with enhanced sealing and waterproofing features to withstand harsh environmental conditions, including exposure to water, dust, dirt, and corrosion. Sealed connectors ensure reliable operation in outdoor and off-road applications, such as commercial vehicles, agricultural machinery, and recreational vehicles.

Future Trends and Innovations

Looking ahead, several trends and innovations are shaping the future of automotive connectivity and connector technology.

Wireless Connectivity: The emergence of wireless connectivity technologies such as Bluetooth, Wi-Fi, and 5G is revolutionizing in-car connectivity, enabling seamless integration of smartphones, wearable devices, and IoT (Internet of Things) devices with vehicle infotainment systems and telematics platforms. Wireless connectors and antennas are becoming increasingly prevalent in modern vehicles, offering greater flexibility, convenience, and accessibility for passengers.

Smart and Adaptive Connectors: Smart connectors equipped with embedded sensors, microcontrollers, and communication protocols enable real-time monitoring, diagnostics, and predictive maintenance of vehicle electrical systems. Adaptive connectors can dynamically adjust their configuration and performance based on changing operating conditions, optimizing energy efficiency, and reliability in diverse environments.

Integration with AI and Edge Computing: The integration of artificial intelligence (AI) and edge computing technologies into automotive connectors enables advanced features such as autonomous driving, predictive analytics, and personalized vehicle experiences. AI-powered connectors can analyze sensor data, detect patterns, and make intelligent decisions in real-time, enhancing vehicle safety, performance, and user satisfaction.

Sustainable Materials and Manufacturing: With growing concerns about environmental sustainability and resource conservation, automotive connector manufacturers are exploring alternative materials and manufacturing processes that minimize environmental impact and promote circular economy principles. Sustainable connectors made from recycled materials, bio-based polymers, and eco-friendly coatings are gaining traction in the automotive industry, aligning with the broader trend towards eco-friendly mobility solutions.

Conclusion

Automotive connectors are the unsung heroes of modern vehicles, enabling seamless communication, functionality, and connectivity between electronic systems and components. As the automotive industry continues to evolve towards electrification, automation, and digitalization, the role of automotive connectors will become increasingly critical in shaping the future of mobility. By embracing advancements in connector technology, automakers can enhance vehicle performance, safety, and user experience while addressing evolving consumer demands and regulatory requirements. As vehicles become more connected, intelligent, and sustainable, automotive connectors will remain at the forefront of innovation, driving the next generation of automotive connectivity solutions.