(Source – spikersolutions.com)

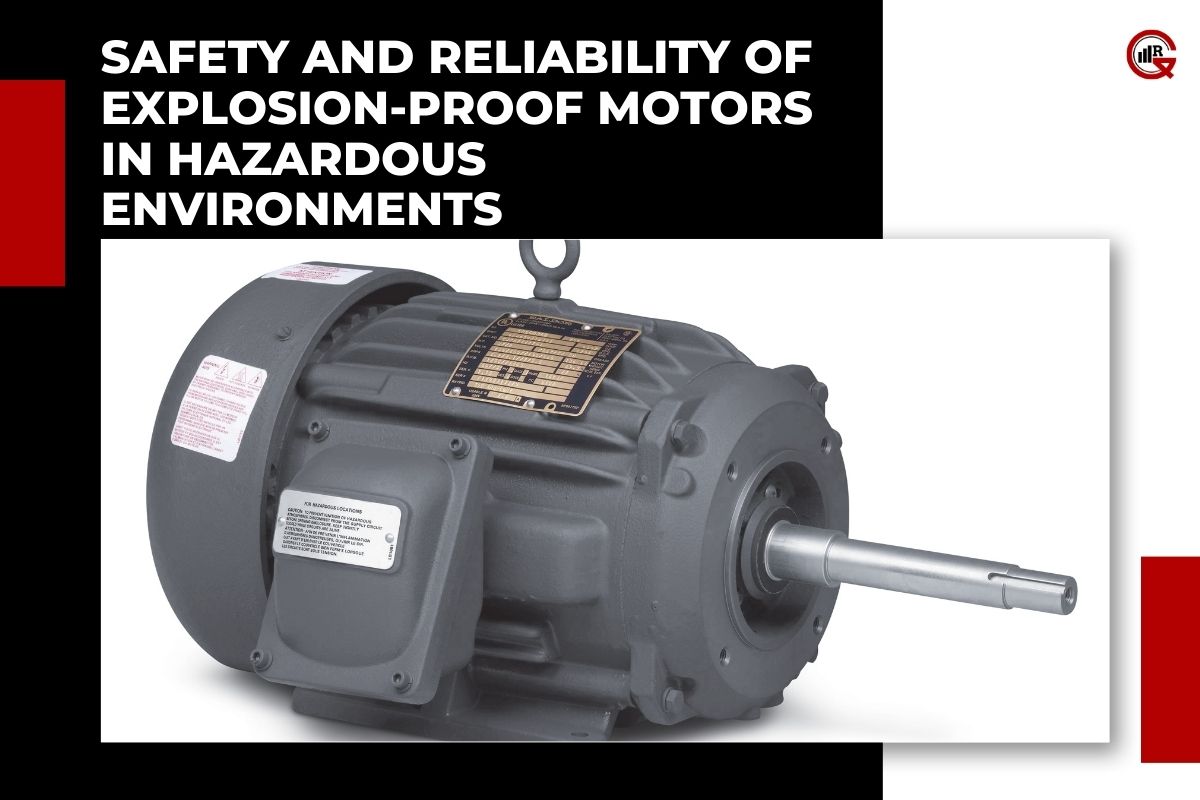

Explosion-proof motors play a critical role in industrial environments where flammable gases, vapors, liquids, or combustible dust are present. These specialized motors are designed to mitigate the risk of explosions by containing sparks and preventing ignition sources from igniting hazardous atmospheres. In this article, we explore the fundamentals, applications, design considerations, and benefits of explosion-proof motors (EPM) in various industries.

Understanding Explosion-Proof Motors

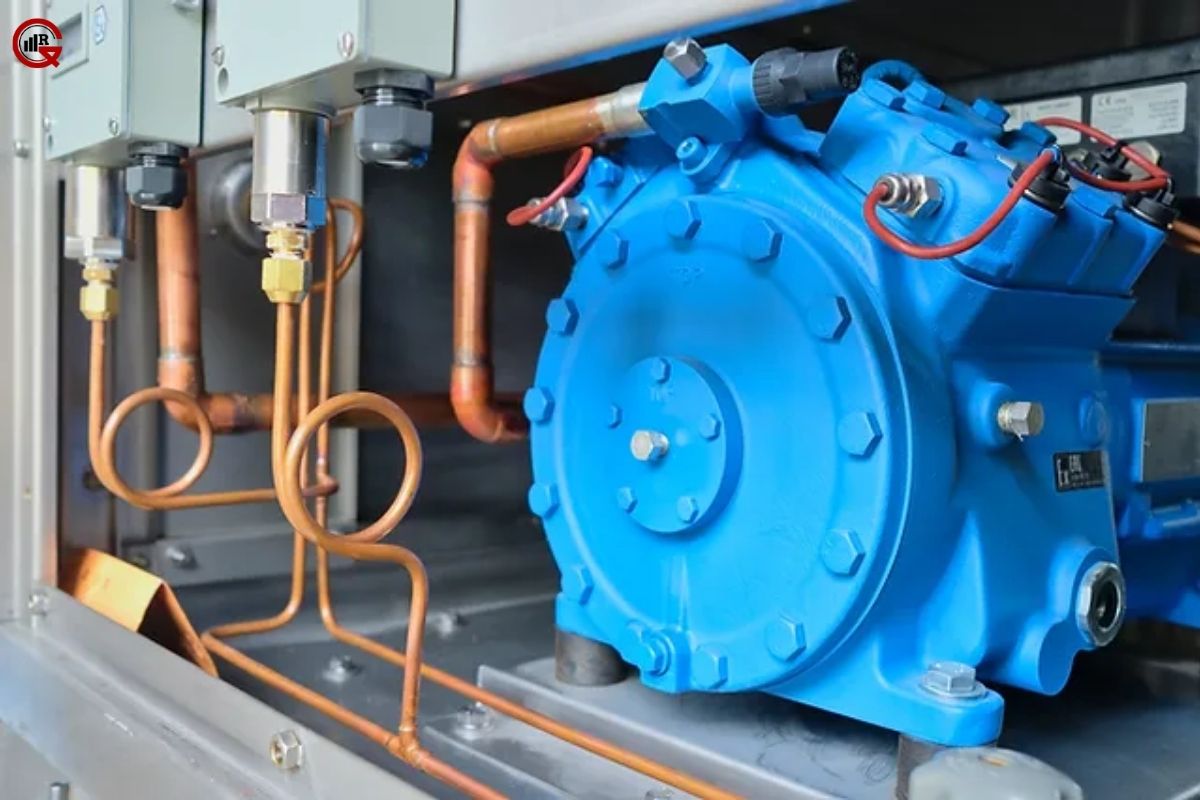

EPMs, also known as hazardous location motors, are engineered to operate safely in environments classified as hazardous due to the presence of combustible materials. These motors are constructed with robust enclosures that can withstand and contain internal explosions, preventing them from igniting the surrounding atmosphere.

The design of EPM is governed by stringent safety standards and regulations, such as those outlined by organizations like the National Electrical Code (NEC), the International Electrotechnical Commission (IEC), and Underwriters Laboratories (UL). These standards dictate the construction, materials, and testing requirements to ensure the motors’ suitability for hazardous locations.

Applications of Explosion-Proof Motors

EPM finds applications in a wide range of industries where the risk of explosions is present. Some common applications include:

Oil and Gas

In the oil and gas industry, explosion-proof motors power equipment such as pumps, compressors, and fans in refineries, drilling rigs, and petrochemical plants. These motors are essential for ensuring safe and reliable operation in hazardous environments where flammable gases and vapors are prevalent.

Chemical Processing

Chemical processing facilities utilize EPM to drive mixers, agitators, and conveyors in areas where volatile chemicals are handled. The motors’ ability to withstand the corrosive effects of chemicals and prevent ignition sources is crucial for maintaining plant safety and productivity.

Mining

EPMs are integral to mining operations, where the presence of combustible dust and methane gas poses significant explosion hazards. These motors power equipment such as conveyor belts, crushers, and ventilation fans in underground mines, providing reliable performance in challenging conditions.

Manufacturing

Manufacturing facilities with processes involving flammable materials, such as paints, solvents, and dust, rely on EPM to drive machinery and equipment. From textile mills to food processing plants, these motors ensure worker safety and regulatory compliance in hazardous work environments.

Pharmaceuticals

In pharmaceutical manufacturing, EPMs are used in equipment such as mixers, granulators, and tablet presses. These motors help mitigate the risk of explosions in areas where volatile chemicals and solvents are handled during drug production.

Design Considerations for Explosion-Proof Motors

Several key design considerations are essential for ensuring the effectiveness and safety of EPM:

Enclosure Construction

EPMs feature robust enclosures constructed from materials that can contain explosions, such as cast iron or aluminum. The enclosure design includes features like flame paths, labyrinth seals, and threaded joints to prevent the propagation of flames and hot gases.

Sealing and Gasketing

Proper sealing and gaskets are critical for preventing the ingress of flammable gases, vapors, or dust into the motor enclosure. EPMs are equipped with high-quality seals and gaskets to maintain the integrity of the enclosure and minimize the risk of ignition.

Temperature Class

Explosion-proof motors are classified based on their maximum surface temperature under normal operating conditions. Temperature classes, such as T1 to T6, indicate the maximum allowable temperature that the motor can reach without posing a risk of ignition. Selecting the appropriate temperature class is essential for compatibility with hazardous atmospheres.

Motor Protection

EPMs may incorporate additional protective features, such as thermal overload protection, bearing temperature monitoring, and explosion-proof conduit fittings. These safeguards help prevent motor failures and reduce the risk of ignition in hazardous locations.

Benefits of Explosion-Proof Motors

The use of EPM offers several benefits for industrial applications:

Enhanced Safety

EPMs provide a high level of safety by containing internal explosions and preventing them from igniting hazardous atmospheres. This helps protect personnel, equipment, and facilities from the devastating consequences of explosions.

Regulatory Compliance

Compliance with safety standards and regulations is a top priority in hazardous environments. EPMs are designed and tested to meet or exceed industry standards, ensuring regulatory compliance and peace of mind for facility operators.

Reliable Performance

EPMs are engineered for ruggedness and reliability, capable of withstanding harsh operating conditions and environmental challenges. Their robust construction and protective features contribute to long-term performance and minimal downtime.

Cost Savings

While the initial cost of EPMs may be higher than standard motors, the potential cost savings from preventing accidents, downtime, and property damage far outweigh the investment. The enhanced safety and reliability of these motors can result in significant long-term savings for industrial facilities.

Conclusion

Explosion-proof motors are indispensable components in hazardous environments where the risk of explosions is present. Engineered with robust enclosures, protective features, and compliance with stringent safety standards, these motors provide a safe and reliable solution for powering equipment in industries such as oil and gas, chemical processing, mining, manufacturing, and pharmaceuticals. By mitigating the risk of ignition and ensuring regulatory compliance, EPMs play a vital role in safeguarding personnel, equipment, and facilities from the potentially catastrophic consequences of explosions. As industries continue to prioritize safety and reliability, the demand for explosion-proof motors is expected to remain strong, driving further advancements in design, technology, and performance.