Description

Global High-Frequency Welder Market Size was worth USD 14.26 Billion in 2023 and it is expected to grow to USD 20.34 Billion in 2030 with a CAGR of 4.30 % in the 2023-2030 period.

Global High-Frequency Welder Market: Overview

Industrial devices called high-frequency welders are used in high-frequency welding procedures, which fuse materials—usually metals—by applying electromagnetic fields with a high frequency. These devices are frequently used to produce pipes, tubes, and other welded components in a variety of industries, such as manufacturing, construction, and automotive.

The general expansion and well-being of the industrial sectors are frequently correlated with the need for high-frequency welders. The demand for effective welding processes is driven by sectors like manufacturing, automotive, and construction. The market may be impacted by developments in welding technology, such as enhanced high-frequency welding equipment. Technological developments that improve accuracy, efficiency, and low energy consumption are frequently welcomed.

Economic factors that affect the demand for high-frequency welders include GDP growth, industrial output, and infrastructure development. These machines are essential for manufacturing and construction activities.

Global High-Frequency Welder Market: Covid-19 Impact

Global supply chains were disrupted by the pandemic as a result of factory closures, travel restrictions, and lockdowns. This might have affected the distribution and manufacturing of high-frequency welders, thereby affecting supply and demand.

-

Decreased Industrial Activity:

As a result of the pandemic, several industries saw delays or brief closures, which had an impact on the market for industrial equipment, particularly high-frequency welders. There were difficulties for the construction and automotive industries, which are major users of welding equipment.

-

Labour Shortages:

Social distancing policies and lockdowns caused a labour shortage across several industries. Manufacturing capacities might have been impacted, which would have affected the production of components related to high-frequency welding.

-

Project Delays:

During the pandemic, a lot of building and industrial expansion projects were postponed or cancelled. This could have resulted in deferred investments in welding equipment.

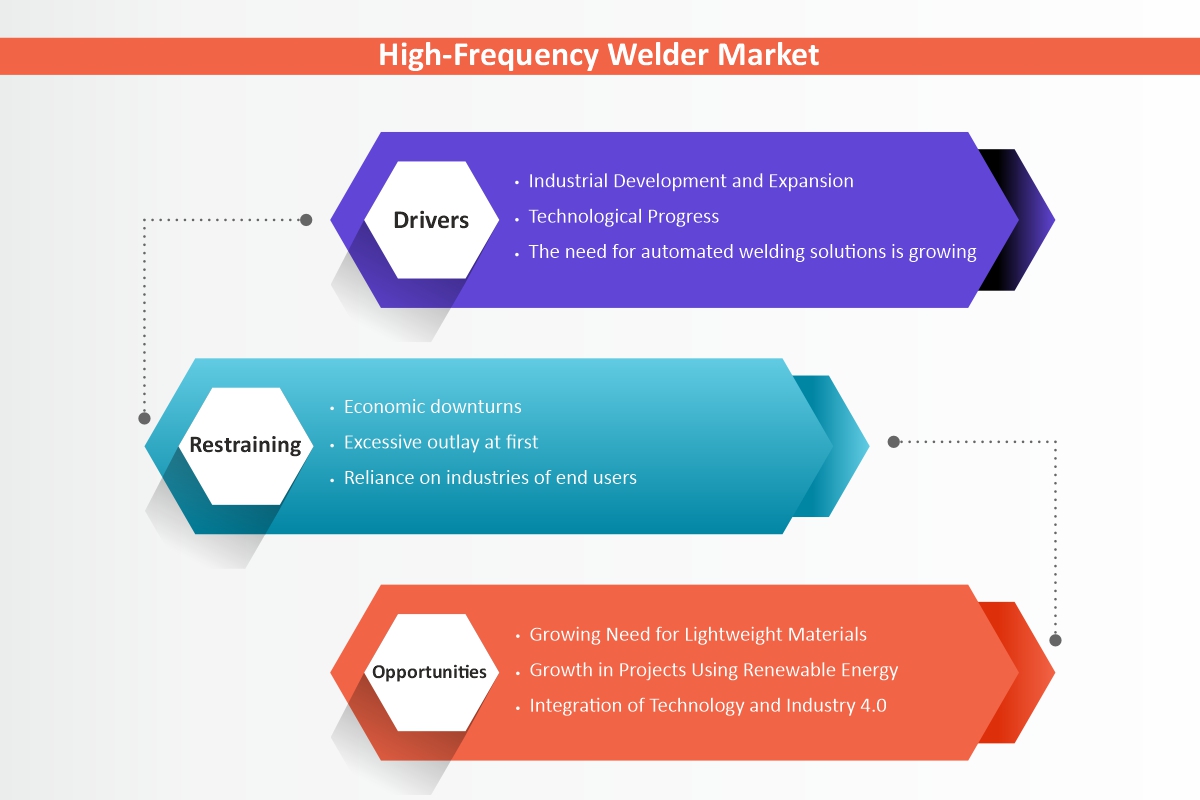

Global High-Frequency Welder Market: Growth Drivers

-

Industrial Development and Expansion:

The need for high-frequency welders is driven by the expansion of industrial sectors like manufacturing, construction, and automotive. These devices are necessary for the fabrication of pipes, tubes, and other welded parts that are utilised in construction projects and industrial operations.

-

Technological Progress:

Continuous improvements in welding technology support the market expansion for high-frequency welders. Innovations that boost the effectiveness, accuracy, and general performance of welding operations can draw in companies seeking to replace their outdated machinery.

-

The need for automated welding solutions is growing.

One important growth driver in manufacturing processes is the trend towards automation. Automation features and robotic system integration make high-frequency welders appealing to industries looking to cut labour costs and improve production efficiency.

Global High-Frequency Welder Market: Restraining factors

-

Economic downturns:

The demand for high-frequency welders may be impacted by decreased manufacturing and infrastructure investments brought on by economic uncertainty and downturns. Businesses may postpone or reduce capital expenditures during unstable economic times.

-

Excessive outlay at first:

Purchasing a high-frequency welder typically requires a substantial upfront cost. Purchasing and setting up this equipment can be expensive, especially for small and medium-sized businesses (SMEs). Adoption rates may be impacted by financial circumstances that restrict access to capital.

-

reliance on industries of end users:

The manufacturing, automotive, and construction end-user industries’ performance has a direct impact on the high-frequency welder market. There could be a domino effect on the need for welding equipment if these industries experience downturns or other disruptions.

Global High-Frequency Welder Market: Opportunity Factors

-

Growing Need for Lightweight Materials:

Lightweight materials, like aluminium and advanced composites, are becoming more and more important to the automotive and aerospace sectors in particular. The increasing demand for lightweight structures presents growth opportunities for high-frequency welders who can join these materials efficiently.

-

Growth in Projects Using Renewable Energy:

Opportunities exist for the high-frequency welder market as a result of the increased focus on renewable energy sources like solar and wind power. These devices are employed in the construction of solar panel supports and wind turbine towers, among other renewable energy infrastructure components.

-

Integration of Technology and Industry 4.0:

High-frequency welders can benefit from integration with Industry 4.0 principles, which include the use of sensors, data analytics, and connectivity. Real-time monitoring, preventative maintenance, and data-driven insights are all possible with smart welding solutions.

Global High-Frequency Welder Market: Challenges

-

Economic Instability:

Economic downturns and uncertainties can result in lower manufacturing and construction investment, which can have an impact on the demand for high-frequency welders. Variations in the state of the world economy could affect companies’ capacity to commit large sums of money to capital projects.

-

High starting expenses:

Purchasing a high-frequency welder typically requires a large upfront cost. The financial resources necessary for the procurement and setup of this equipment may pose a challenge for small and medium-sized enterprises (SMEs) or companies with constrained financial resources.

-

Market Competition:

There is competition in the high-frequency welder market, with multiple manufacturers providing comparable products. Price wars resulting from fierce competition may have an impact on industry profit margins for participating businesses.

Global High-Frequency Welder Market: Segmentation

The market is divided into solid-state and vacuum tube HF welders based on product type. Electron tubes or vacuum tubes are used by vacuum tube high-frequency welders to produce high-frequency currents. Although solid-state technology advancements have made these types of welders less common in modern applications, they might still be useful in some industrial contexts.

Packaging, Automotive, Electrical and Electronics, Medical, and Other are the market segments based on application. Precision welding is frequently needed in the electrical and electronics industry to manufacture components like circuit boards, connectors, and electronic enclosures. For these applications, high-frequency welders can deliver the required precision.

Global High-Frequency Welder Market: Regional Insights

North America has a well-established manufacturing and construction sector, especially in the United States and Canada. Developments in the energy sector, automobile manufacturing, and infrastructure projects all have an impact on the need for high-frequency welders in this area.

Europe boasts a strong manufacturing sector, with activities in the automotive, aerospace, and construction industries driving the need for high-frequency welders. The adoption of cutting-edge welding technologies may be influenced by the region’s emphasis on sustainability and adherence to stringent environmental regulations.

A major force in the world’s manufacturing scene, the Asia-Pacific area is home to nations like China, Japan, and India. The region’s fast infrastructure growth, industrialization, and car manufacturing all contribute to the need for high-frequency welders. The market is also shaped by factors like cost and the availability of skilled labour.

In Latin America, the need for high-frequency welders is frequently associated with building and infrastructure projects. The state of the economy, government spending, and the general expansion of industrial activity all affect the dynamics of the market in this area.

The Middle East’s infrastructure development projects are a major factor in the demand for high-frequency welders. An additional factor driving the need for welding equipment is the oil and gas sector. financial circumstances. Economic conditions and geopolitical factors can impact market trends in this region.

Global High-Frequency Welder Market: Competitive Landscape

Thermatool Corp., Rollform India, Taicang Global Machinery, Sifang Sanyi, Chenguan Technology, NIRMAL OVERSEAS PRIVATE LTD., Zemat Technology Group, INDUCTOTHERM GROUP, Surya Electric, HEBEI SANSO MACHINERY, and Liaoning Unify High-Frequency Equipment.