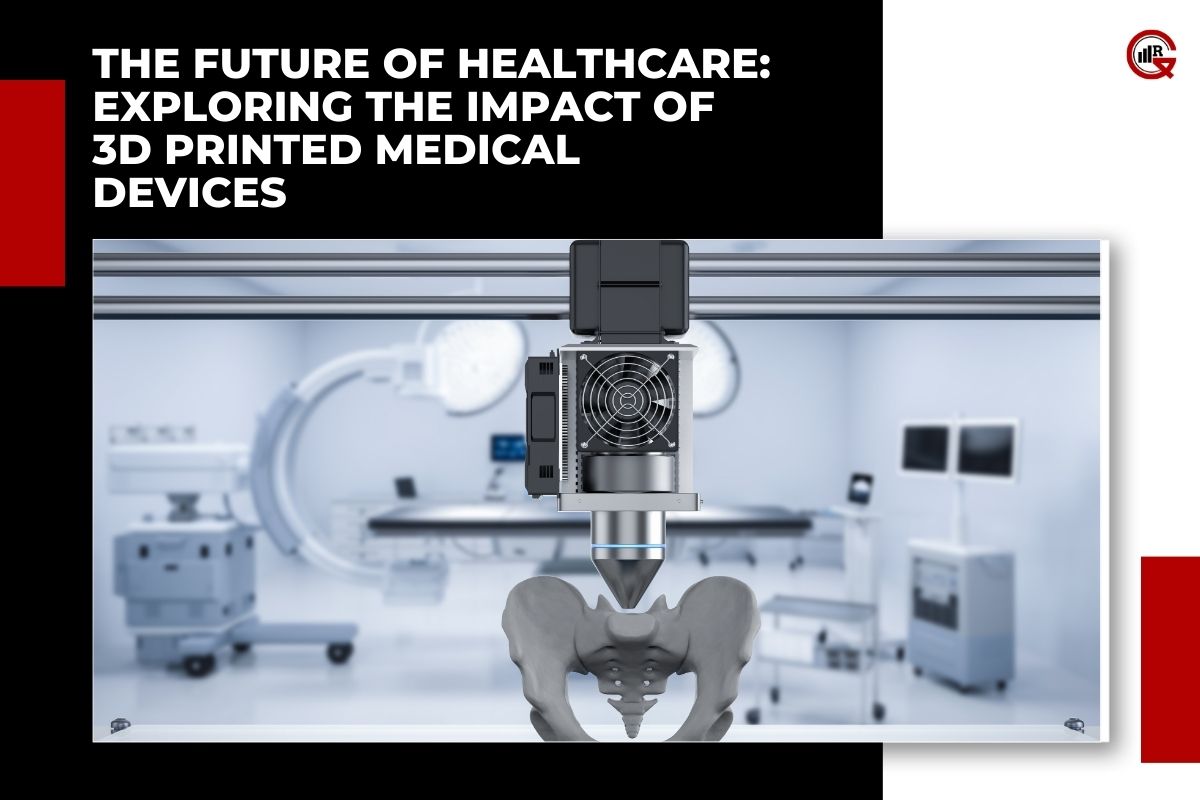

In recent years, the advent of 3D printing technology has revolutionized numerous industries, with healthcare being one of the most significantly impacted sectors. The ability to create custom, patient-specific medical devices through 3D printing is transforming medical practices, improving patient outcomes, and driving advancements in personalized medicine. This article delves into the world of 3D printed medical devices, exploring their fabrication, benefits, current applications, and future potential.

Understanding 3D Printing in Medicine:

3D printing, also known as additive manufacturing, involves creating three-dimensional objects layer by layer from a digital model. In the medical field, this technology is used to produce a variety of devices, from surgical instruments to prosthetics and implants. The process typically includes the following steps:

Digital Modeling: The first step involves creating a digital model of the device using computer-aided design (CAD) software. This model can be based on patient-specific data obtained from imaging techniques such as MRI or CT scans.

Material Selection: Choosing the appropriate material is crucial for the device’s functionality and biocompatibility. Common materials include biocompatible plastics, metals, and even living cells for tissue engineering.

Printing Process: Various 3D printing technologies, such as stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM), are used to print the device. Each technology offers unique advantages depending on the material and application.

Post-Processing: After printing, the device may undergo additional processes such as sterilization, surface finishing, and assembly to ensure it meets the required standards for medical use.

Testing and Validation: The final step involves rigorous testing to validate the device’s performance, safety, and effectiveness before it can be used in a clinical setting.

Advantages of 3D Printed Medical Devices:

3D printed medical devices offer numerous advantages over traditional manufacturing methods:

Customization: One of the most significant benefits is the ability to create patient-specific devices tailored to individual anatomical structures. This customization enhances the fit, comfort, and effectiveness of medical devices.

Rapid Prototyping: 3D printing enables rapid prototyping, allowing for quick iterations and testing of new designs. This accelerates the development process and reduces the time required to bring new devices to market.

Complex Geometries: Additive manufacturing can produce complex geometries that are difficult or impossible to achieve with traditional manufacturing techniques. This capability is particularly beneficial for creating intricate structures like porous implants and vascular stents.

Cost-Effectiveness: While the initial investment in 3D printing technology can be high, the ability to produce small batches and reduce material waste can result in cost savings over time. Additionally, the customization reduces the need for expensive molds and tooling.

Improved Patient Outcomes: Custom-fit devices lead to better patient outcomes by enhancing comfort, reducing recovery times, and improving overall treatment effectiveness. For example, custom prosthetics and orthotics can significantly improve mobility and quality of life for patients.

Current Applications:

The versatility of 3D printing technology has led to its adoption in various medical applications:

Prosthetics and Orthotics: 3D printing allows for the creation of custom prosthetics and orthotics tailored to the unique anatomy of each patient. These devices offer improved fit, comfort, and functionality compared to off-the-shelf options.

Surgical Instruments: Surgeons can benefit from 3D printed surgical instruments that are customized for specific procedures. These instruments can be designed to improve precision, reduce surgical time, and minimize patient trauma.

Implants: Custom 3D printed implants, such as orthopedic and dental implants, are becoming increasingly common. These implants can be tailored to fit the patient’s anatomy perfectly, reducing the risk of complications and improving outcomes.

Tissue Engineering: Researchers are exploring the use of 3D bioprinting to create living tissues and organs. By printing layers of living cells, scientists aim to develop functional tissues for transplantation, drug testing, and disease modeling.

Medical Models: 3D printed anatomical models based on patient-specific imaging data are valuable tools for surgical planning and education. Surgeons can use these models to visualize complex structures, plan procedures, and practice surgeries.

Future Prospects:

The future of 3D printed medical devices is filled with exciting possibilities driven by ongoing advancements in materials science, printing technologies, and regulatory frameworks. Some key trends and future directions include:

Bioprinting: The development of 3D bioprinting technology holds the potential to revolutionize organ transplantation. By printing layers of living cells and biomaterials, researchers aim to create functional organs that could address the shortage of donor organs and eliminate the need for immunosuppressive drugs.

Personalized Medicine: As the field of personalized medicine advances, 3D printed medical devices will play a crucial role in tailoring treatments to individual patients. Custom drug delivery systems, personalized implants, and patient-specific surgical instruments are just a few examples of how this technology will enhance personalized care.

Advanced Materials: The discovery and development of new biocompatible materials will expand the range of applications for 3D printed medical devices. Materials with improved mechanical properties, bioactivity, and degradation rates will enable the creation of more effective and durable devices.

Regulatory Frameworks: As 3D printing technology becomes more prevalent in healthcare, regulatory bodies are developing guidelines and standards to ensure the safety and efficacy of 3D printed medical devices. These frameworks will help streamline the approval process and foster innovation.

Integration with Digital Health: The integration of 3D printing with digital health technologies, such as wearable devices and telemedicine, will create new opportunities for remote monitoring, personalized treatments, and patient-specific interventions. For instance, 3D printed wearables could be used to monitor vital signs and deliver targeted therapies.

Conclusion:

3D printed medical devices represent a transformative advancement in healthcare, offering unparalleled customization, improved patient outcomes, and the potential for rapid innovation. From prosthetics and implants to surgical instruments and tissue engineering, the applications of this technology are vast and continually expanding. As advancements in materials science, bioprinting, and personalized medicine continue to evolve, 3D printed medical devices are poised to play an increasingly critical role in shaping the future of healthcare. The ongoing integration of this technology into clinical practice promises to enhance patient care, reduce healthcare costs, and drive the next wave of medical breakthroughs.