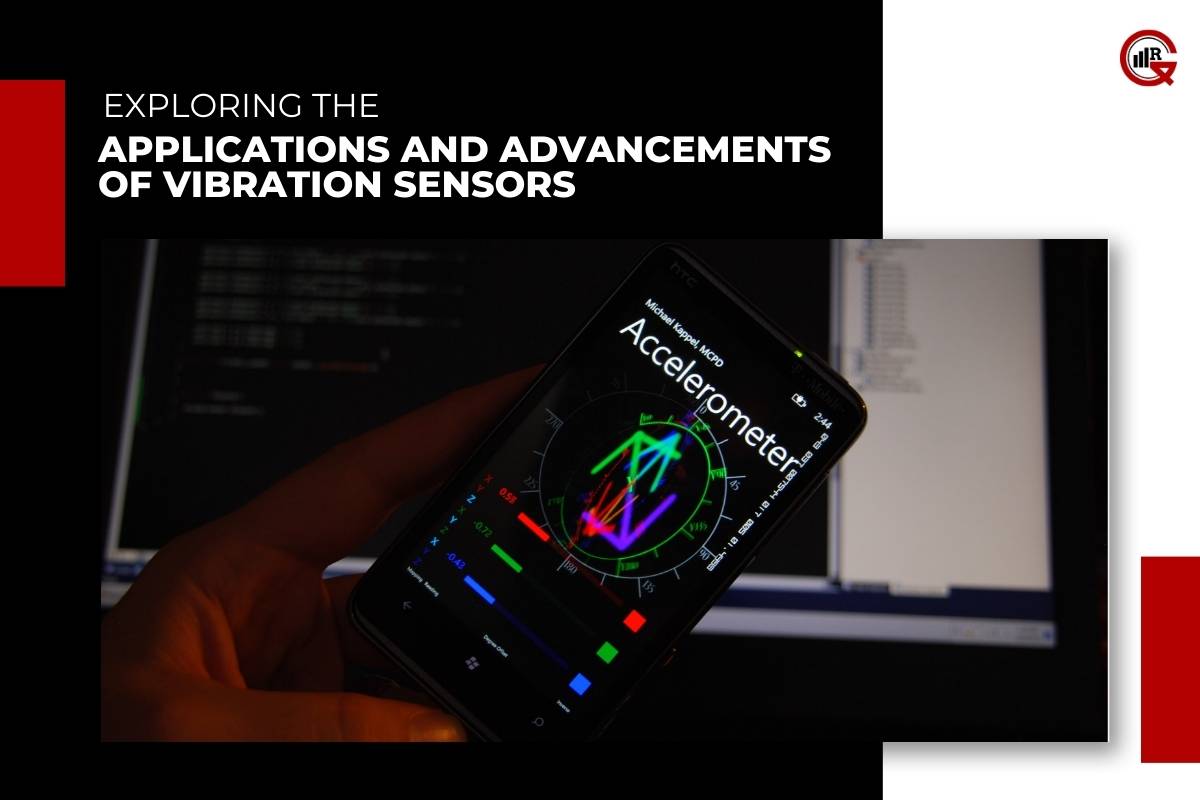

Vibration sensors, also known as accelerometers, play a crucial role in various industries and applications, from automotive engineering to structural health monitoring. These devices detect and measure vibrations in machinery, structures, and other systems, providing valuable insights into their performance, condition, and safety. This article delves into the fundamentals of vibration sensors, their diverse applications, recent advancements, and prospects.

Fundamentals of Vibration Sensors:

They operate based on the principle of detecting changes in acceleration or velocity caused by vibrations. They typically consist of a mass suspended on a spring within a housing, with a piezoelectric crystal or capacitive element to measure the resulting displacement. When subjected to vibrations, the mass moves relative to the housing, generating a signal proportional to the acceleration or velocity experienced.

Applications in Industry:

Vibration sensors find extensive use in industrial machinery monitoring and predictive maintenance. By continuously monitoring vibrations in rotating equipment such as motors, pumps, and turbines, these sensors can detect anomalies indicative of impending failures, allowing for timely maintenance interventions to prevent costly downtime. Additionally, sensors are employed in automotive applications for vehicle health monitoring, engine diagnostics, and safety systems.

Structural Health Monitoring:

In civil engineering and infrastructure, sensors play a vital role in structural health monitoring (SHM). They are used to assess the dynamic behavior of bridges, buildings, dams, and other structures under various loads, including wind, seismic activity, and traffic. By monitoring vibrations, engineers can detect structural defects, assess integrity, and ensure the safety and longevity of critical infrastructure.

Advancements in Vibration Sensor Technology:

Recent advancements in vibration sensor technology have led to improved sensitivity, accuracy, and miniaturization. Micro-electro-mechanical systems (MEMS) technology has enabled the development of miniature vibration sensors with high performance and low power consumption, suitable for integration into portable devices and IoT applications. Additionally, advancements in signal processing algorithms and wireless connectivity have enhanced the capabilities of vibration monitoring systems for real-time data analysis and remote monitoring.

Wireless Vibration Monitoring Systems:

Wireless vibration monitoring systems offer several advantages over traditional wired systems, including ease of installation, flexibility, and cost-effectiveness. These systems consist of wireless sensors deployed throughout a facility or asset, transmitting data to a central monitoring system for analysis and decision-making. Wireless connectivity enables real-time monitoring of equipment health, allowing for proactive maintenance and improved operational efficiency.

Condition-Based Maintenance:

Condition-based maintenance (CBM) strategies leverage vibration sensors and other predictive maintenance technologies to monitor equipment health and perform maintenance tasks only when necessary. By monitoring vibration signatures and trend analysis, CBM systems can identify early signs of degradation or faults, enabling maintenance teams to schedule repairs during planned downtime, minimize unplanned outages, and extend equipment lifespan.

Challenges and Opportunities:

Despite their widespread adoption and benefits, sensors face certain challenges, including environmental factors, signal noise, and data interpretation complexities. Additionally, integrating vibration monitoring systems into existing infrastructure and workflows may require investments in equipment, training, and software integration. However, with ongoing advancements in sensor technology, data analytics, and connectivity, the potential for innovation and application of vibration sensors continues to expand across industries.

Future Trends and Outlook:

Looking ahead, the future of vibration sensors holds promise for further miniaturization, increased sensitivity, and enhanced integration with IoT and AI technologies. The advent of Industry 4.0 and the proliferation of smart sensors and connected devices are driving demand for advanced vibration monitoring solutions capable of delivering actionable insights in real time. As industries strive for greater efficiency, reliability, and safety, sensors will remain indispensable tools for monitoring equipment health and optimizing asset performance.

Emerging Applications:

In addition to traditional uses, vibration sensors are finding new applications in emerging fields such as wearable technology, healthcare, and environmental monitoring. In wearable devices, these sensors can track human motion, detect falls, and monitor physical activities, enhancing fitness tracking and healthcare monitoring capabilities. In healthcare, sensors are being explored for applications such as gait analysis, sleep monitoring, and prosthetic limb control. Furthermore, in environmental monitoring, sensors are used to detect seismic activity, monitor structural integrity, and assess the impact of human activities on ecosystems.

Integration with Artificial Intelligence:

The integration of sensors with artificial intelligence (AI) and machine learning (ML) algorithms is revolutionizing predictive maintenance and fault diagnosis. AI-driven vibration analysis can identify subtle patterns and anomalies in vibration data, enabling predictive maintenance models to predict equipment failures with greater accuracy and reliability. By continuously learning from historical data and real-time sensor inputs, AI-powered systems can adapt to changing operating conditions and optimize maintenance schedules for maximum efficiency and cost savings.

Remote Monitoring and Diagnostics:

Remote monitoring capabilities offered by sensors enable real-time monitoring of equipment health and performance from anywhere in the world. By transmitting vibration data wirelessly to cloud-based platforms, maintenance teams can remotely monitor the condition of critical assets, diagnose potential issues, and prioritize maintenance activities. This remote monitoring approach minimizes the need for on-site inspections, reduces travel costs, and enables proactive maintenance interventions, ultimately improving asset reliability and uptime.

Interdisciplinary Collaboration:

The interdisciplinary nature of vibration sensor technology fosters collaboration between engineers, data scientists, and domain experts from various fields. Cross-disciplinary collaboration facilitates the development of innovative solutions and applications that address complex challenges in diverse industries. By leveraging expertise from multiple disciplines, teams can design customized vibration monitoring systems tailored to specific use cases, optimize sensor placement and configuration, and enhance data analysis techniques for improved predictive maintenance and performance optimization.

Conclusion:

Vibration sensors play a critical role in monitoring machinery, structures, and systems across various industries, enabling predictive maintenance, structural health monitoring, and condition-based maintenance strategies. Recent advancements in sensor technology, wireless connectivity, and data analytics are driving innovation and expanding the applications of vibration sensors. As industries embrace digital transformation and the era of smart manufacturing, the importance of sensors in ensuring operational efficiency, safety, and reliability will continue to grow.