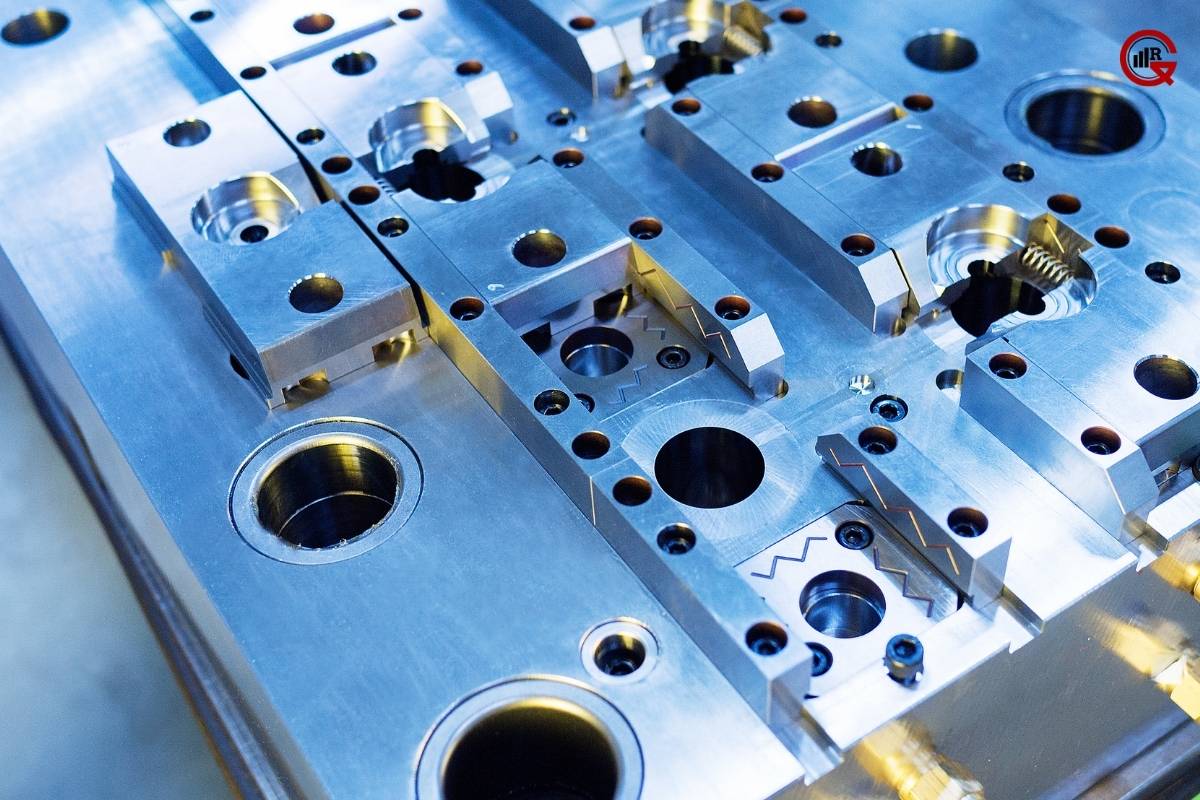

Metal Injection Molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength and durability of metal materials. This innovative technique has gained popularity in various industries, including automotive, aerospace, medical, and electronics, for its ability to produce complex metal parts with high precision and cost-effectiveness. However, like any manufacturing process, MIM has its own set of advantages and disadvantages. In this comprehensive guide, we’ll explore the key benefits and drawbacks of Metal Injection Molding.

Advantages of Metal Injection Molding:

1. Complex Geometries

One of the most significant advantages of MIM is its ability to produce complex, intricate, and precision-engineered parts that would be difficult or impossible to manufacture using traditional methods. MIM allows for the creation of parts with intricate features, thin walls, and precise tolerances, making it ideal for components with intricate shapes and tight dimensional requirements.

2. High Density and Strength

MIM produces parts with high density and excellent mechanical properties, comparable to those of conventionally manufactured metal parts. The resulting parts exhibit high strength, hardness, and wear resistance, making them suitable for demanding applications where durability and reliability are essential.

3. Cost-Effectiveness

MIM offers cost savings compared to traditional machining or casting processes, especially for complex parts with intricate geometries. By combining multiple manufacturing steps into a single process and minimizing material waste, MIM reduces production time, labor costs, and material expenses, resulting in overall cost savings for manufacturers.

4. Material Versatility

MIM is compatible with a wide range of metal materials, including stainless steel, titanium, aluminum, copper, and nickel-based alloys. This versatility allows manufacturers to produce parts with specific material properties tailored to the requirements of their applications, such as corrosion resistance, thermal conductivity, or magnetic properties.

5. Design Flexibility

MIM offers design flexibility, allowing engineers to create custom parts with intricate features and complex geometries without the limitations of traditional manufacturing processes. Parts can be designed with undercuts, internal threads, fine details, and multi-level structures, opening up new possibilities for product innovation and optimization.

Disadvantages of Metal Injection Molding:

1. High Initial Investment

Implementing MIM requires significant upfront investment in specialized equipment, tooling, and infrastructure. The initial capital expenditure can be substantial, particularly for small to medium-sized manufacturers or companies new to MIM technology, making it a barrier to entry for some businesses.

2. Limited Material Selection

While MIM offers versatility in terms of compatible materials, the range of available alloys may be limited compared to traditional metalworking processes. Certain materials, such as high-temperature alloys or exotic metals, may be challenging to process using MIM due to their unique properties or processing requirements.

3. Longer Lead Times

Metal Injection Molding typically involves longer lead times compared to other manufacturing processes, primarily due to the complex tooling and production setup required. Designing and fabricating molds, conducting prototyping and testing, and optimizing process parameters can extend the time-to-market for MIM-produced parts, which may not be suitable for time-sensitive projects or applications.

4. Part Size Limitations

Metal Injection Molding is best suited for producing small to medium-sized parts with intricate geometries. Large and bulky components may be challenging to manufacture using MIM due to limitations in mold size, material flow, and cooling rates. Manufacturers may need to explore alternative production methods for oversized or non-standard parts.

5. Quality Control Challenges

Maintaining consistent quality and dimensional accuracy is crucial in Metal Injection Molding, given the complexity of the process and the precision required for intricate parts. Quality control measures such as process monitoring, inspection, and testing are essential to ensure that parts meet the specified requirements and standards. However, detecting defects or discrepancies in MIM-produced parts can be challenging, requiring advanced inspection techniques and expertise.

6. Environmental Impact

Metal Injection Molding can have both positive and negative environmental implications. On one hand, MIM offers the potential for reduced material waste compared to traditional machining processes, as it allows for the precise shaping of metal powders into near-net shape parts. Additionally, the ability to recycle excess material and reuse scrap metal can contribute to overall sustainability. However, the energy-intensive nature of the MIM process, particularly during sintering, may result in higher energy consumption and greenhouse gas emissions. Manufacturers should strive to implement energy-efficient practices and explore opportunities for renewable energy sources to minimize the environmental footprint of Metal Injection Molding.

7. Surface Finish and Post-Processing

While MIM can produce parts with intricate shapes and precise dimensions, achieving a high-quality surface finish directly from the mold may be challenging. Parts may require additional post-processing steps such as machining, polishing, or coating to achieve the desired surface texture and appearance. These secondary operations can add complexity and cost to the manufacturing process and may impact lead times. Manufacturers should carefully plan and optimize post-processing techniques to ensure the desired surface finish while minimizing additional time and resources.

8. Tooling Maintenance and Replacement

The molds and tooling used in MIM are subject to wear and tear over time, particularly due to the high temperatures and pressures involved in the process. Regular maintenance and periodic replacement of molds may be necessary to maintain product quality and consistency. Manufacturers should factor in the costs associated with tooling maintenance and replacement when evaluating the overall economic viability of Metal Injection Molding for their production needs.

9. Regulatory Compliance

Depending on the industry and application, MIM may be subject to regulatory standards and requirements governing materials, processes, and product performance. Manufacturers must ensure compliance with relevant regulations and standards to meet quality assurance, safety, and legal obligations. This may involve conducting material testing, certification, and documentation to demonstrate adherence to industry-specific requirements. Failure to comply with regulatory standards can result in costly fines, product recalls, and damage to the company’s reputation.

10. Technology Advancements and Innovations

As with any manufacturing process, Metal Injection Molding continues to evolve with advancements in technology and innovations in materials, equipment, and process optimization. Emerging trends such as additive manufacturing integration, digital twin simulations, and multi-material MIM are expanding the capabilities and possibilities of MIM, opening up new opportunities for complex part production and customization. Manufacturers should stay informed about the latest developments in MIM technology and explore ways to leverage these advancements to enhance productivity, quality, and competitiveness.

Conclusion: Making Informed Decisions

In conclusion, Metal Injection Molding offers a unique combination of advantages and disadvantages that make it a compelling manufacturing solution for certain applications. The ability to produce complex, high-precision metal parts with excellent mechanical properties at a competitive cost makes MIM an attractive option for industries ranging from automotive and aerospace to medical and consumer electronics.

However, it’s essential for manufacturers to carefully weigh the pros and cons of MIM and consider factors such as initial investment, material selection, lead times, part size limitations, and quality control requirements when evaluating its suitability for their specific needs. By making informed decisions and leveraging the strengths of Metal Injection Molding while mitigating its limitations, companies can harness the full potential of this innovative manufacturing technology to drive innovation, efficiency, and competitiveness in their respective industries.