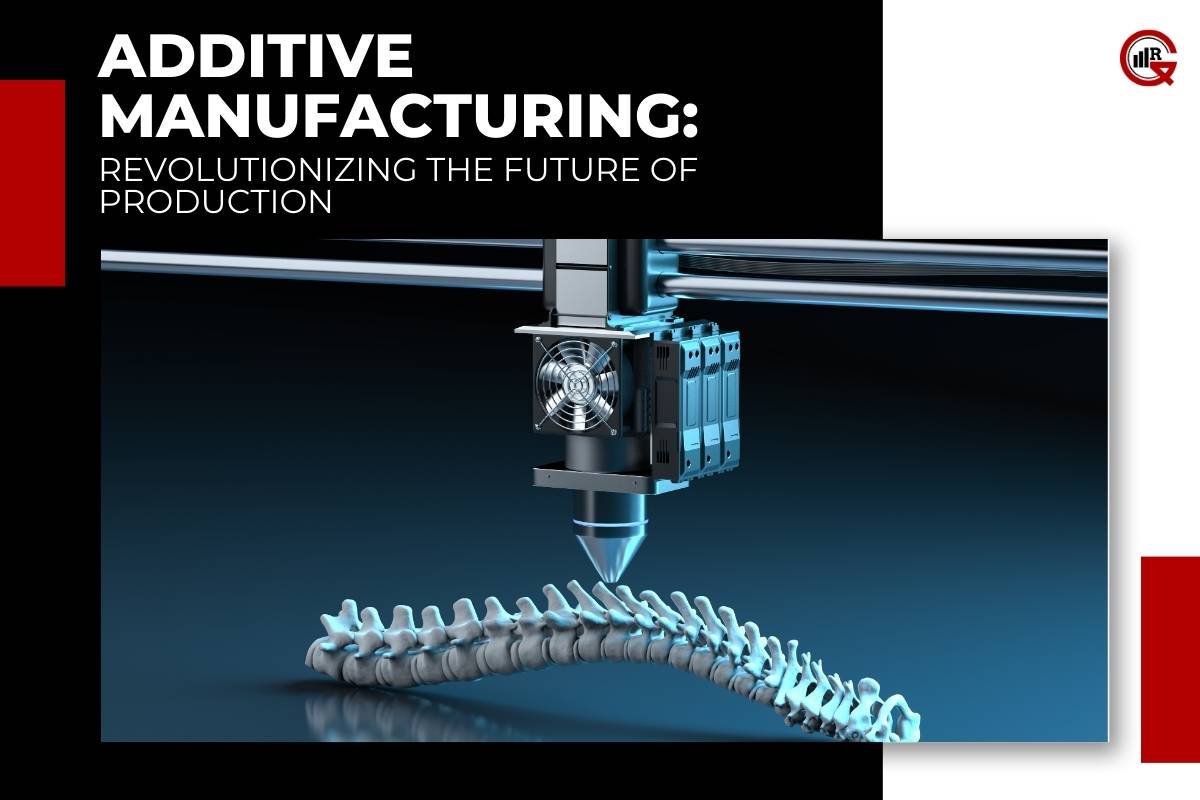

Additive manufacturing, also known as 3D printing, has emerged as a transformative technology with the potential to revolutionize the way we design, produce, and distribute goods. From rapid prototyping to custom manufacturing, manufacturing offers unprecedented flexibility, efficiency, and innovation across a wide range of industries. In this article, we delve into the world of manufacturing, exploring its history, applications, benefits, and prospects.

A Brief History of Additive Manufacturing

The concept of manufacturing dates back to the 1980s when the first 3D printing techniques were developed. Initially used for rapid prototyping in the aerospace and automotive industries, manufacturing has since evolved into a versatile manufacturing process capable of producing complex geometries with precision and efficiency. Over the years, advances in materials science, software development, and manufacturing technologies have expanded the capabilities of additive manufacturing, enabling its widespread adoption across various sectors.

Applications of Additive Manufacturing

Manufacturing finds applications in diverse industries, including aerospace, automotive, healthcare, consumer goods, and architecture, among others. Some notable applications of manufacturing include:

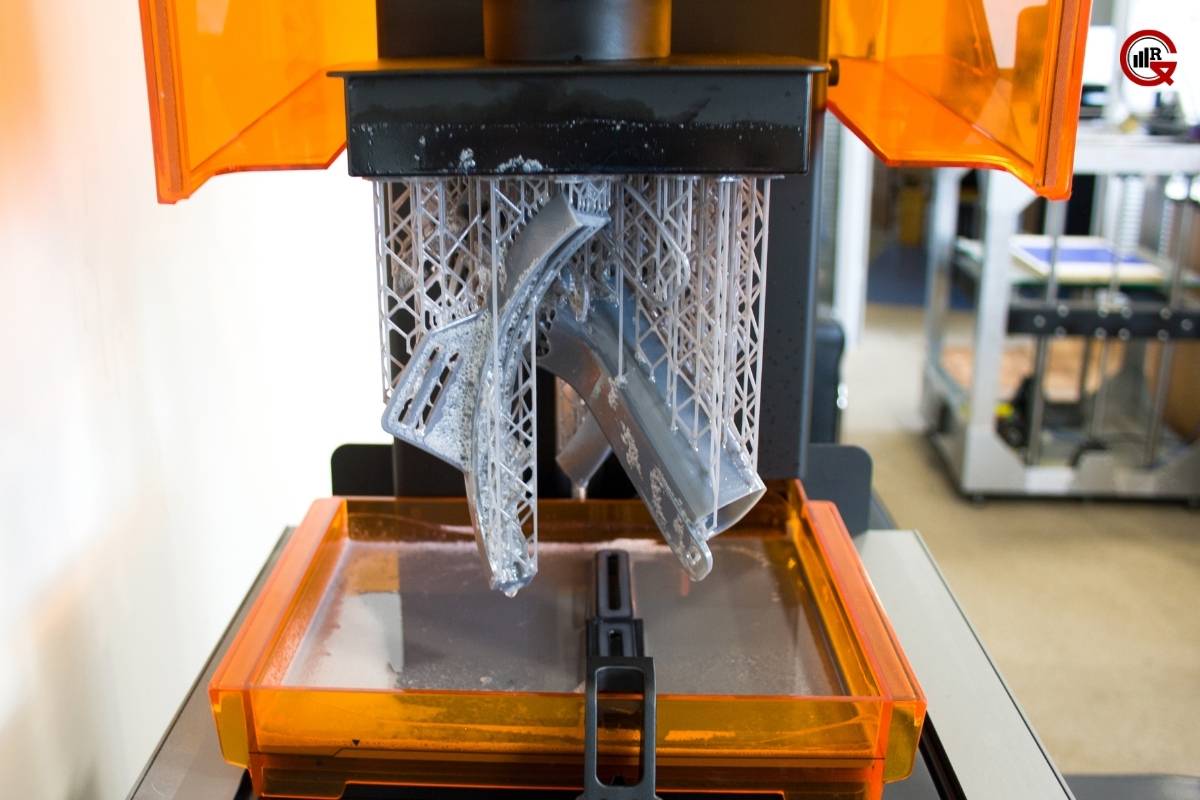

Prototyping: Additive manufacturing allows engineers and designers to quickly iterate and refine product designs by producing physical prototypes with minimal lead time. This rapid prototyping capability accelerates the product development cycle and enables faster time-to-market for new products.

Custom Manufacturing: Manufacturing enables the production of customized parts and components tailored to specific customer requirements. Whether creating personalized medical implants, custom-fit prosthetics, or bespoke jewelry, manufacturing offers unparalleled flexibility in manufacturing highly individualized products.

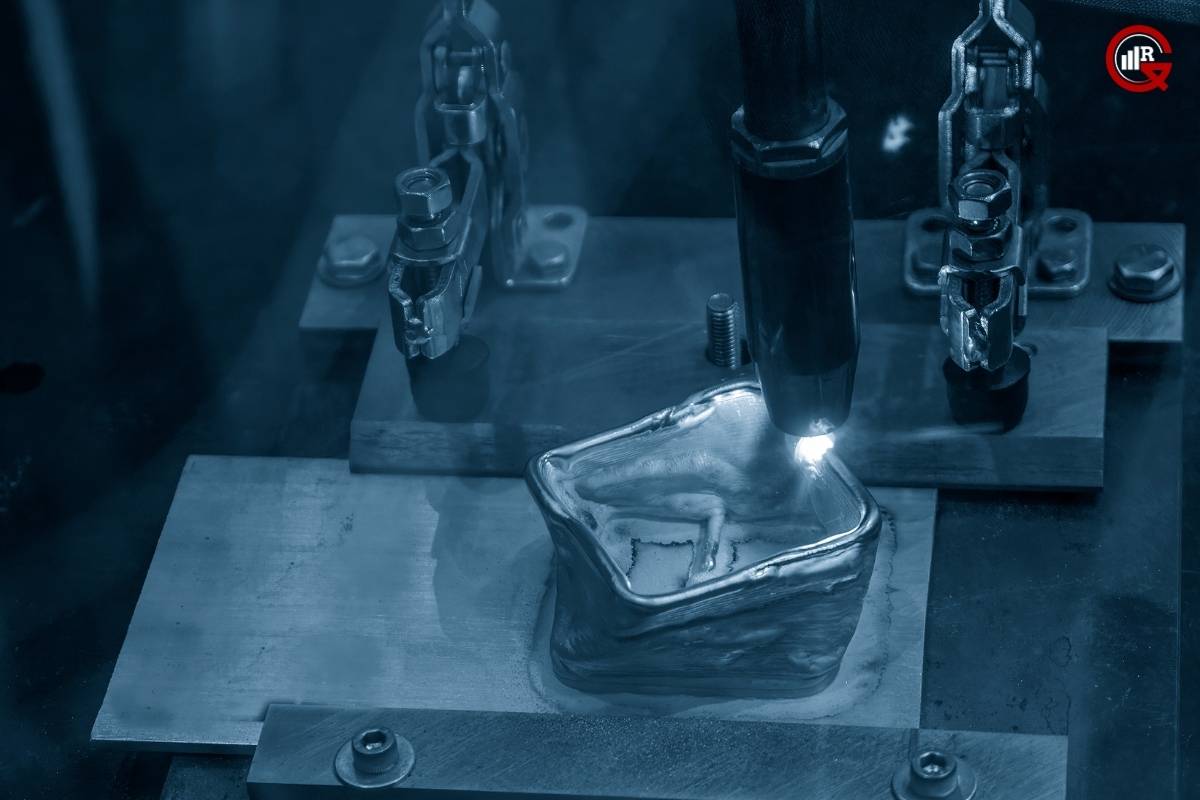

Tooling and Jigs: Manufacturing is increasingly used for the rapid production of tooling, jigs, and fixtures used in manufacturing processes. By leveraging 3D printing technology, manufacturers can create lightweight, durable, and complex tooling solutions that improve efficiency, reduce lead times, and lower production costs.

Production Parts: Manufacturing is being adopted for the direct production of end-use parts and components in various industries. From aerospace components to automotive parts, manufacturing offers the potential to produce lightweight, high-performance components with intricate geometries and superior mechanical properties.

Benefits of Additive Manufacturing

The adoption of such type of manufacturing method offers several compelling benefits for businesses and industries:

Design Freedom: Manufacturing enables the production of complex geometries and intricate designs that are difficult or impossible to achieve using traditional manufacturing methods. This design freedom allows engineers and designers to explore new possibilities and innovate without the constraints of conventional manufacturing processes.

Cost Savings: Manufacturing can reduce production costs by minimizing material waste, streamlining production workflows, and eliminating the need for costly tooling and molds. By producing parts on-demand and in-house, businesses can also reduce inventory costs and mitigate supply chain risks.

Rapid Iteration: The rapid prototyping capabilities of manufacturing enable engineers and designers to quickly iterate and refine product designs based on feedback and testing. This iterative design process accelerates innovation, reduces time-to-market, and enhances product quality and performance.

Customization: Manufacturing allows for the cost-effective production of customized products and components tailored to individual customer requirements. Whether creating personalized medical devices, consumer products, or industrial components, manufacturing enables mass customization at scale.

Future Prospects of Additive Manufacturing

The future of additive manufacturing holds tremendous promise for continued innovation and advancement. Some key areas of development and research include:

Materials Innovation: Researchers are exploring new materials and composites optimized for manufacturing processes, including metals, polymers, ceramics, and biomaterials. These advanced materials offer enhanced mechanical properties, thermal stability, and biocompatibility, expanding the range of manufacturing applications.

Process Optimization: Ongoing research aims to improve the speed, accuracy, and efficiency of manufacturing processes through advancements in hardware, software, and process optimization techniques. From multi-material printing to automated post-processing, these developments promise to enhance productivity and scalability in amanufacturing.

Sustainability: Additive manufacturing has the potential to contribute to sustainability efforts by reducing material waste, energy consumption, and environmental impact compared to traditional manufacturing methods. Researchers are exploring bio-based materials, recycling techniques, and closed-loop manufacturing systems to further enhance the sustainability of manufacturing.

Industrial Adoption: As manufacturing technologies mature and production capabilities expand, we can expect to see increased adoption of manufacturing in industrial-scale production environments. From aerospace and automotive manufacturing to healthcare and construction, manufacturing will play a growing role in shaping the future of production.

Conclusion:

In conclusion, manufacturing represents a paradigm shift in manufacturing technology, offering unprecedented flexibility, efficiency, and innovation across industries. With its ability to produce complex geometries, customize products, and streamline production workflows, manufacturing is poised to transform the way we design, produce, and distribute goods in the 21st century. As research and development efforts continue to push the boundaries of additive manufacturing technology, we can anticipate further advancements, applications, and opportunities that will shape the future of production for years to come.