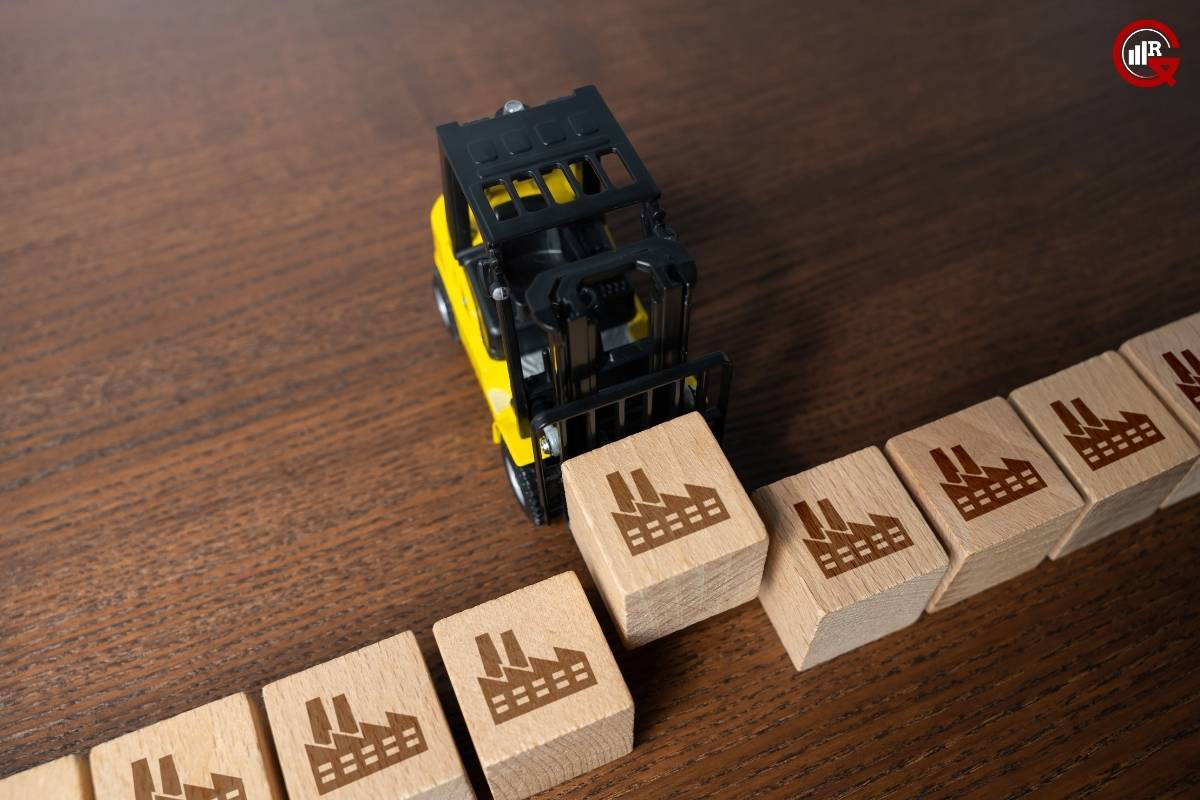

In the intricate web of global supply chains, one critical component stands out for its pivotal role in preserving the integrity of temperature-sensitive products: the cold chain. From pharmaceuticals and vaccines to perishable foods and biologics, the cold vaccine serves as a lifeline, maintaining optimal temperature conditions from production to distribution, ensuring product safety and efficacy. In this article, we explore the intricacies of cold chain logistics, its significance across various industries, and the challenges and innovations driving its evolution.

Understanding A Complex Journey

It refers to a series of interconnected processes and infrastructure designed to maintain specific temperature ranges for the transportation, storage, and handling of temperature-sensitive products. These products, which include vaccines, blood products, fresh produce, dairy products, and certain medications, require precise temperature control to prevent spoilage, degradation, or loss of efficacy.

The journey of a temperature-sensitive product through the chain begins at the point of manufacture or production, where it is carefully packaged and stored under controlled conditions. From there, the product is transported via refrigerated trucks, ships, or planes to distribution centers, warehouses, and ultimately to end-users or consumers. At each stage of the cold chain, temperature monitoring and control mechanisms are employed to ensure compliance with specified temperature requirements and regulatory standards.

Significance Across Industries: From Pharmaceuticals to Food

The cold chain logistics plays a critical role in various industries, each with its unique set of temperature-sensitive products and requirements:

Pharmaceuticals and Biologics: Pharmaceutical products, including vaccines, biologics, and certain medications, are highly sensitive to temperature fluctuations. Deviations from recommended temperature ranges can compromise product efficacy and safety, leading to potential health risks for patients. The cold chain is essential for maintaining the potency and stability of pharmaceutical products throughout their lifecycle, from manufacturing to distribution and administration.

Food and Beverage: Perishable foods, including fresh produce, dairy products, meat, and seafood, require refrigeration or freezing to maintain quality and safety. The cold chain logistics ensure that these products remain fresh and free from contamination during transportation and storage, reducing the risk of foodborne illnesses and spoilage. Additionally, the cold chain enables the global trade of perishable foods, allowing consumers to access a diverse range of fresh products year-round.

Biotechnology and Life Sciences: Temperature-sensitive biologics, such as enzymes, antibodies, and reagents used in research and diagnostics, require stringent temperature control to preserve their activity and stability. The cold chain is essential for maintaining the integrity of biological products, ensuring reliable results, and reproducibility in scientific experiments and clinical assays.

Chemicals and Industrial Products: Certain industrial products, chemicals, and materials may also be sensitive to temperature variations and require specialized cold chain logistics solutions to prevent degradation or alteration of their properties. From electronic components to adhesives and coatings, maintaining consistent temperature conditions is essential for ensuring product quality and performance.

Challenges and Innovations in Cold Chain Logistics Management

Despite its critical importance, the cold chain presents numerous challenges and complexities that require innovative solutions and continuous improvement:

Temperature Monitoring and Control: Accurate temperature monitoring and control are paramount in cold chain management to prevent temperature excursions and ensure product quality and safety. Advances in sensor technology, data analytics, and real-time monitoring systems have enhanced visibility and control over temperature-sensitive products, enabling proactive intervention and response to temperature deviations.

Infrastructure and Logistics: The effective management of cold chain logistics relies on robust infrastructure, including refrigerated storage facilities, transportation equipment, and cold chain packaging solutions. However, inadequate infrastructure, especially in remote or developing regions, can pose challenges to maintaining the integrity of the cold chain and distributing temperature-sensitive products safely and efficiently.

Regulatory Compliance: Regulatory requirements and standards governing cold chain logistics vary across industries and regions, adding complexity to cold chain management. Ensuring compliance with Good Distribution Practices (GDP), Good Manufacturing Practices (GMP), and other regulatory frameworks is essential for safeguarding product quality, meeting customer expectations, and avoiding regulatory penalties or sanctions.

Sustainability and Environmental Impact: The cold chain consumes significant energy and resources, contributing to environmental degradation and greenhouse gas emissions. Sustainable cold chain practices, such as energy-efficient refrigeration technologies, optimized transportation routes, and recyclable packaging materials, are essential for minimizing the environmental footprint of cold chain logistics and promoting sustainable development.

Conclusion

In conclusion, the cold chain is a vital component of modern supply chains, ensuring the integrity and safety of temperature-sensitive products across various industries. From pharmaceuticals and biologics to food and beverages, cold chain logistics plays a critical role in preserving product quality, efficacy, and safety from production to consumption. However, the complexity of the cold chain presents challenges that require innovative solutions and collaboration across stakeholders to overcome. By embracing technology, adopting best practices, and prioritizing sustainability, we can enhance the resilience and efficiency of the cold chain, ensuring the uninterrupted flow of temperature-sensitive products to meet the needs of consumers worldwide.